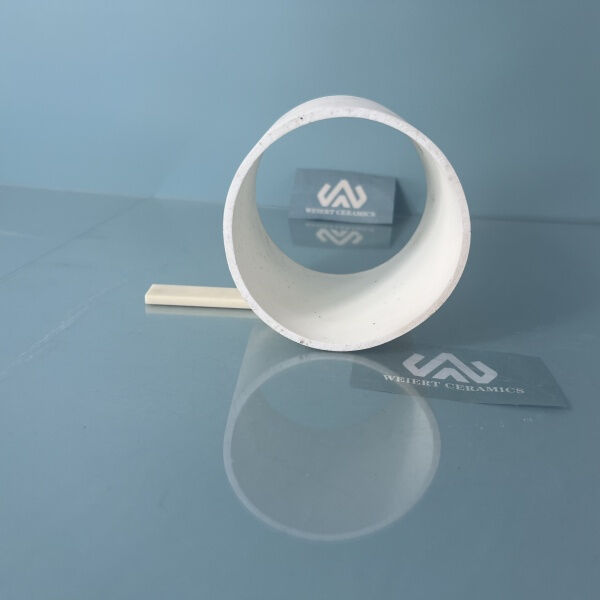

Ceramic Shaft Sleeve: The Innovative Choice for a Safer and Higher Quality Solution

Today ceramic shaft sleeves are among the growing innovations the market. Its advantages include its quality, safety, longer service life, and lots of more. The utilization of Weiert Ceramics Ceramic wear parts has become more popular in numerous industries as they offer better performance and protection for rotating machinery. We will talk about the many benefits and just how you are able to effectively use them.

Ceramic shaft sleeves offer several unmatched benefits by traditional sleeves. The first bonus is their high resistance to put on and tear. Ceramic shaft sleeves are constructed with high-quality materials, which means that they are less likely to deteriorate quickly. What this means is their lifespan is longer, and you will save yourself more money on replacements. Another advantage is that Weiert Ceramics zirconia sleeves offer thermal-shock great resistance. This means that they can withstand high temperatures, going to be useful in many industrial applications. This feature ensures that the sleeve remains in excellent condition even yet in the surrounding temperature quickly.

The next advantage is its innovation. Innovations in design of ceramic shaft sleeves have brought about improvements that can cause them to become more effective and efficient within their use. Weiert Ceramics ceramics in automotive industry manufacturers have designed ceramic shaft sleeves to cater towards the wants of numerous applications that can be industrial making them suitable to be used in several machines.

Ceramic shaft sleeves are also safer to work with. In comparison to traditional bronze plastic sleeves, Weiert Ceramics aluminum oxide ceramic can withstand greater stresses and pressures without wearing down. Why them less hazardous to utilize, decreasing the risk of accidents and accidents in the workplace. Furthermore, they truly are much easier to work alongside as they possibly can quickly replace existing sleeves without the necessity to rework other parts.

Ceramic shaft sleeves are built to produce better quality and service. The standard of the sleeves is incomparable to traditional sleeves simply because they offer better protection and gratification, important in the industrial planet. Additionally, Weiert Ceramics alumina ceramic material offer longer service life, meaning reduced downtime of machinery, which translates to increased productivity. And you also find yourself saving more money into the long term they might need little maintenance.

Flexible Options Weiert offers personalized customization services our clients. understand each customer's needs are unique. By establishing a clear communication with customers are able create products that fully satisfy their particular requirements application. can adapt any specific requirements of customer whether it is product dimensions ceramic shaft sleeve, or performance parameters.

Strict Inspection Weiert has established an extensive quality management system has been awarded ISO International Quality Certification. continuously monitor all aspects of production adhere to the industry's standards regulations. Each step, from raw materials selection inspection of the product and inspection at the end, is subjected meticulous quality control in order to ensure the most efficient performance of product. Our quality control team that is ceramic shaft sleevesystematic sampling and testing to detect potential problems and ensure our customers have confidence.

Quick Delivery Weiert is equipped with latest production equipment a large capacity to ensure the timely delivery orders to customers. have improved our production processes shorten delivery cycles and improve production efficiency. Even for large-volume orders, are able complete manufacturing and delivery within agreed timeframe. We have also established long-term partnerships with reliable logistic providers ceramic shaft sleeveyour products are delivered securely and quickly our customers.

Weiert consistently delivers. With more than decade's ceramic shaft sleevein high-end ceramics as well as extensive knowledge, Weiert able to deliver products of the highest quality. From complex structures, simple designs, we adhere high standards and strict standards produce high-quality products. company has a well-established production process that rigorously control over every step from raw materials until finished products, ensuring consistent product quality.

The versatility of ceramic shaft sleeves makes them useful in many applications being different. A few of the most common applications of ceramic shaft sleeves through the protection of water pumps, chemical pumps, slurry pumps, and chemical and biological treatment. Weiert Ceramics alumina ceramic parts are also suitable within the papermaking process, where they protect the paper and pulping machines. They could also be employed within the beverage and food industry, and many other applications.