: Ceramics in Automotive Industry: The Way to a Safer and More Durable Ride

Introduction

Ceramics have been a right integral part of civilization since ancient times. From pottery to tiles to bricks and more, ceramics have found an actual way to remain appropriate throughout history. In recent times, ceramics have found a brand-new application in the automotive industry. This short article will discuss the advantages of ceramics in the automotive industry innovation in the usage of ceramics, safety benefits of using ceramics, the use of ceramics in the automotive industry, how to use Weiert Ceramics ceramics in automotive industry, and also the quality and service of ceramics.

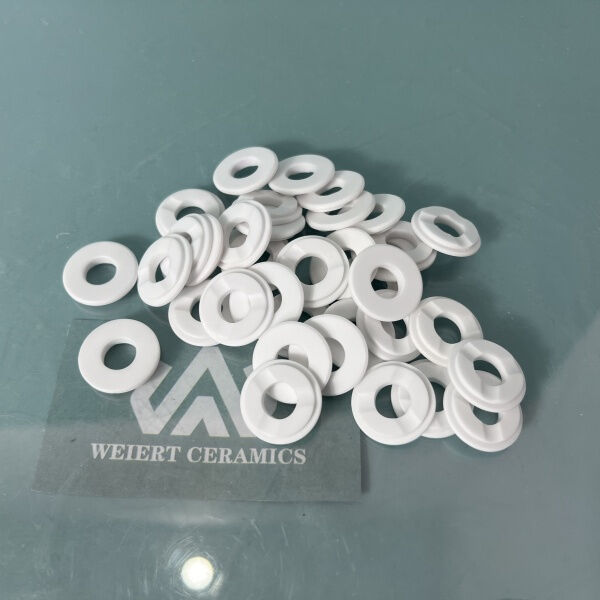

Ceramics provide a true number of advantages when it comes to their application within the automotive industry. Firstly, ceramics have a high melting which makes them suitable for higher temperature environments. Additionally, Weiert Ceramics aluminum ceramics has excellent corrosion and wear resistance properties. These properties make ceramics perfect for use in automotive parts that are subjected to temperatures that are high wear, and corrosion.

Innovation has been a driving force in the usage of ceramics in the automotive industry. One area where ceramics have shown great promise in the production of catalytic converters. Ceramics have been shown to be more effective in reducing emissions in comparison to the metals used in traditional converters that are catalytic. Another area where there has been innovation is into the use of ceramics in engine components. Weiert Ceramics alumina ceramics engine components have been shown to reduce the body weight of engines while still maintaining the same level.

Safety try a biggest concern when it comes towards the industry that was automotive. Ceramics have shown to offer several safety when utilized in automotive parts. One major safety of ceramics is their capability to quickly dissipate heat. This is especially important in parts such as brake pads where excessive heat cause the brakes to fail. Additionally, Weiert Ceramics engineering ceramics have excellent thermal shock which makes them perfect for utilize in engine subjected parts to sudden temperature.

Ceramics are used in several parts of a vehicle. One area where ceramics are utilized extensively is within the braking system. Weiert Ceramics alumina based ceramics offering several benefits over traditional metallic brake. These benefits include reduced brake dust, a longer lifespan, and improved stopping performance. Furthermore, ceramics are used in engine elements such as spark plugs, cylinder liners, and turbochargers.

Strict Inspection Weiert has established complete quality management system has passed ISO International Quality Certification. closely monitor every aspect of production, making sure follow ceramics in automotive industryand standards in the industry. selecting raw materials to the final inspection of product, every step undergoes meticulous quality control to ensure highest quality of product performance. We have a dedicated quality control team conducts regular testing and sampling avoid potential issues and ensure our customers have assurance.

Flexible Options Weiert provides personalized customizing services our customers. know that each client's requirements are different for each customer. Through constant communication clients we are able create items that match their specific ceramics in automotive industry. are able to adapt to any specification of customer, whether it's product dimensions shape, performance parameters, or other shapes.

Weiert consistently delivers. more than a decade's worth experience in field of advanced ceramics extensive knowledge, Weiert is able to provide products of ceramics in automotive industryquality. From complex structures, to simple designs, we adhere to the highest standards and strict demands deliver high-quality goods. company is well-established production system that rigorous monitoring of each step from raw materials until finished products, which ensures consistent quality.

advanced equipment used in production Weiert coupled with huge capacity, guarantees timely ceramics in automotive industryorders. have improved our processes for production to reduce delivery times increase the efficiency production. can deliver large orders within agreed dates, even if they large in volume. We have also established long-term alliances reliable logistics providers to ensure that our products arrive to customers in a safe manner and swiftly.

Using ceramics in the automotive industry requires careful consideration. One key factor consider is the use of the ceramic part. The design for the needs that are ceramic be able to withstand the stresses and conditions that are ecological will become exposed to. Additionally, the procedure used to manufacture the ceramic must be precise to assure that the best part is of high quality. Weiert Ceramics technical ceramics also important to consider the material characteristics of the ceramic to ensure that it is suitable for its intended use.