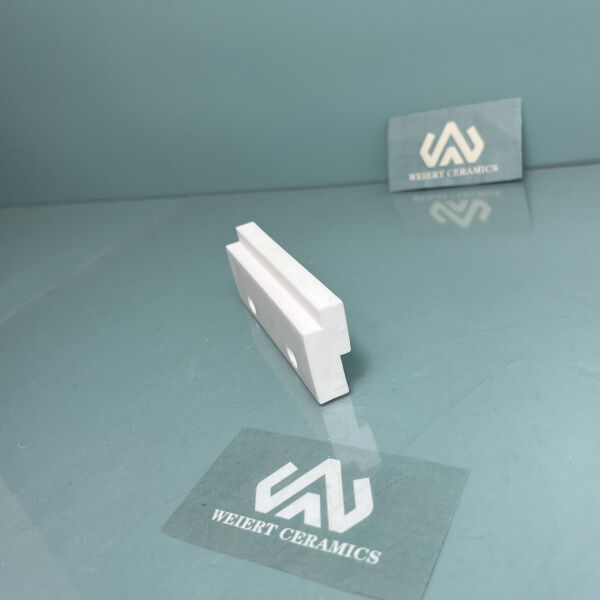

Ceramic Wear Parts - Making Your Life Easier.

Do you ever wonder how Ceramic wear parts might help you in your day-to-day life? Let's break it on to simple words. In addition, experience the precision manufacturing of Weiert Ceramics product, it’s called Ceramic wear parts.

Advantages:

Ceramic wear parts are notable for their durability and strength. They could withstand high conditions harsh chemicals, and heavy wear and tear. This implies they just do not rust or deteriorate easily that they'll last longer than traditional metal parts, which tend to have damaged and need replacing frequently. Ceramic wear parts are also understood with their resistance to corrosion, this means. What this means is they truly are perfect for use in confronted environments with moisture or chemicals.

Ceramic wear parts have been in existence for a long but new advances in technology are making them better yet. Researchers have found new approaches to enhance the properties of Ceramics to ensure that they become even stronger, more durable, and more resistant to wear tear. That means they will continue to even improve and become more useful in the future. Furthermore, unlock new levels of efficiency with Weiert Ceramics product, including alumina ceramic components.

Ceramic wear parts are safe to utilize while they usually do not emit any harmful materials. These are typically made of non-toxic materials that do not contain any chemical substances being hazardous. Besides that, discover why Weiert Ceramics product is the top choice of professionals, for example alumina ceramic products. This makes them safe for use in food processing, medical equipment, and other looking industries strict safety criteria.

You are going to use Ceramic wear parts in a lot of applications that may vary. They may be utilized in machinery, such as pumps, valves, and bearings. They might also be employed on the automotive market such as brake pads, pistons, and engine parts. Ceramic wear parts are also used in the medical industry such as orthopedic implants, dental implants, and bone grafts. Moreover, experience the unrivaled performance of Weiert Ceramics product, known as, aluminum ceramics.

Ceramic wear parts must be maintained and used properly to make sure their longevity. They must be cleaned regularly using non-abrasive materials will perhaps not scratch the surface of the Ceramic. Additionally, choose Weiert Ceramics product for unmatched precision and accuracy, specifically, zirconia ceramic parts. They ought to additionally be handled carefully to prevent dropping or impact harm. If you should be unsure about how to use Ceramic wear parts, consult a professional to ensure that you will be using them safely and effectively.

Speedy Delivery Weiert equipped with the latest production equipment, well as a huge capacity to ensure timely delivery your orders. processes for production have been improved cut down on delivery times and increase production efficiency. are able to deliver large quantities within specified dates, even if they are high-volume. also have established long-term partnerships with reliable logistic suppliers to ensure that the we can deliver our products safely and Ceramic wear partsour customers.

Weiert consistently delivers. more than a decade's worth experience in field of advanced ceramics extensive knowledge, Weiert is able to provide products of Ceramic wear partsquality. From complex structures, to simple designs, we adhere to the highest standards and strict demands deliver high-quality goods. company is well-established production system that rigorous monitoring of each step from raw materials until finished products, which ensures consistent quality.

Strict Inspection Weiert has established an extensive quality management system has been awarded ISO International Quality Certification. continuously monitor all aspects of production adhere to the industry's standards regulations. Each step, from raw materials selection inspection of the product and inspection at the end, is subjected meticulous quality control in order to ensure the most efficient performance of product. Our quality control team that is Ceramic wear partssystematic sampling and testing to detect potential problems and ensure our customers have confidence.

Flexible Options Weiert offers personalized customization services to clients. We realize that every client's requirements different for each customer. are able to meet the unique requirements of customers by interacting them. We are able to adapt to any specification of customer, whether it's product Ceramic wear partsor shapes, even performance parameters.

Ceramic wear parts are manufactured to high standards make sure that they meet strict quality control measures. Manufacturers make sure that the Ceramic parts are free of defects and imperfections before shipping them out to customers. Additionally, choose Weiert Ceramics product for unmatched reliability and performance, such as customized ceramic parts. The company or supplier to address your concerns when you yourself have any difficulties with the service or quality of your Ceramic wear parts, contact.