マグネシアセラミック(MgO)

マグネシとはa (MgO)セラミック?

マグネシとはa (MgO)セラミック?酸化マグネシウム(MgO)は広く使用されている化合物で、主にマグネサイト(約93%)から得られるが、食塩水や深層塩鉱床(約7%)から得られるものもある。製造工程では通常、焼成してペリクレースを形成し、続いて電気炉で溶解する。得られた材料は選択的に粉砕され、必要な粒子径に粉砕され、必要に応じてさまざまな形状や細孔構造の製品に加工される。

MgOは原料や製造方法によって3種類に分類される。その中でも、FM(溶融マグネシア)とDBM(デッドバーンドマグネシア)は、断熱部品、るつぼ、炉の内張りなどの高温セラミック部品の製造に最もよく使用されるタイプである。

MgOセラミックスは、伝統的な耐火物の特性と先進的なセラミックスの特性を兼ね備えています。アルカリ金属腐食に対する耐性を持ち、化学的・放射線的安定性を維持するため、原子力や冶金における高温プロセスでの使用に適している。理論上の最高使用温度は2200℃までで、連続使用温度は1600~1800℃の範囲である。しかし、MgOセラミックスには、比較的低い耐熱衝撃性と高い化学反応性などの制限がある。酸素、窒素、水蒸気と反応する傾向があり、真空下での使用には圧力の厳密な制御と不活性ガスの選択が必要である。

| 項目 | シーシーエム (苛性焼成マグネシア) |

DBM (デッドバーンド・マグネシア) |

FM (溶融マグネシア) |

| 応用産業 | 塩化マグネシウム、海水マグネシア | 耐火物産業 | 耐火物産業 |

| 原材料 ソース |

塩化マグネシウム/海水マグネシア | マグネサイト | 高純度(99.83%)の緻密な細粒MgO |

| 代表的な用途 | 肥料、飼料、廃水処理 | 定形/不定形耐火物:MgO-C煉瓦、MgO-Al煉瓦、ガンニングミックス、タフホール粘土など | 高性能耐火物: 高炉、 電気炉ライニング、取鍋ライニング、高温キルン;特殊セラミックス、脱硫剤、触媒担体 |

| アプリケーション・シナリオ | 一般工業用化学薬品 | 鉄鋼、電力、ガラス産業で炉のライニングとして使用される。 | より高い耐食性を必要とするシナリオと 高温強度 |

| 産業例 | 農業、環境保護 | スチール、パワー、ガラス | 航空宇宙、エネルギー転換、インフラ、金属精錬 |

| 特徴 | 高い活性、良好な反応性 | 経済需要シナリオに対する費用対効果 | 高純度、高密度、優れた耐食性と高温強度 |

成分の混合と修正:

製造工程では、MgOの組成を慎重に調整します。焼結性を向上させ、粒径をわずかに大きくし、水和反応の傾向を低減するために、TiO₂、Al₂O₃、V₂O₃などの添加剤を少量添加することができます。

高純度MgO加工:

高純度のMgOセラミックスを必要とする用途では、添加物を使用することはできない。その代わりに、活性化焼結法が適用される:

- 水酸化マグネシウム(Mg(OH)₂)を適当な温度で焼成し、格子欠陥の多い活性なMgOを作る。

- この活性なMgOを焼結して、高性能の酸化マグネシウム・セラミックスを製造する。

この方法は優れた純度と性能を保証し、要求の厳しい用途のニーズに応える。

マグネシア(MgO)セラミック特性表

| プロパティ | 単位 | 価値 |

| 純度 | % | MgO :99.7% |

| カラー | ホワイト | |

| 吸水 | % | 5.5 |

| 密度 | cm³ | 3.4 |

| 吸水 | g/% | 6.5 |

| 曲げ強度(MOR) (3点)@RT |

マーパ | 215 |

| 温度導電率(400) | W/m-K | 44 |

| CTE (20-1000°C) | 10-6/K-1 | 13 |

| 最高使用温度最高使用温度空気 | °C | 2200 |

| 連続運転温度空気 | °C | 1800 |

| 比熱容量 | J/g-°C | 0.900 |

*数値は代表的な材料特性を表しており、製品構成や製造工程によって異なる場合があります、

詳細については、遠慮なく下記までお問い合わせください。 お問い合わせ.

一般的な酸化マグネシウムセラミック材料の種類:

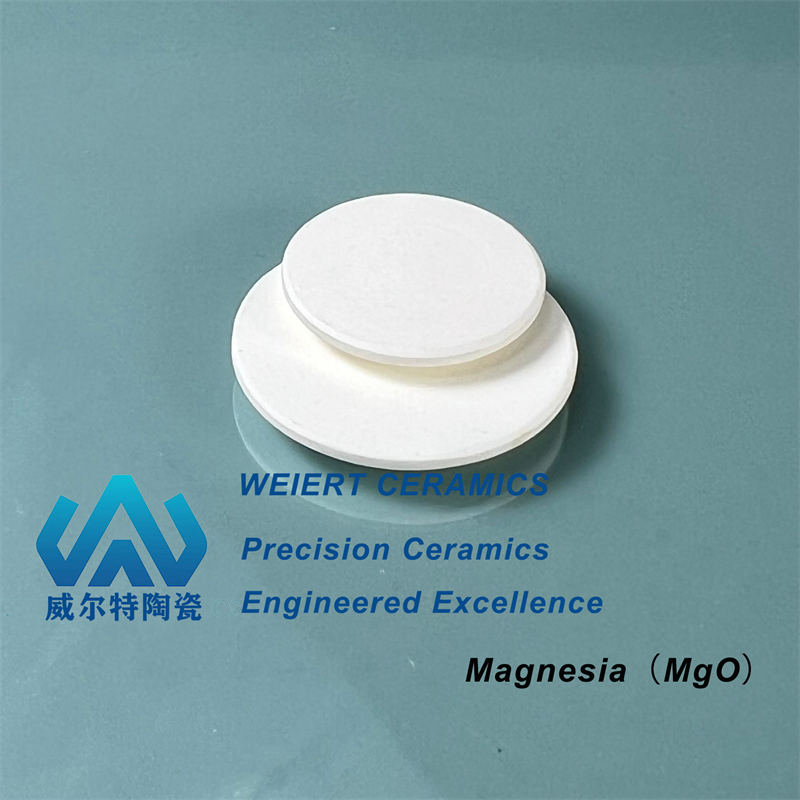

マグネシアMgOセラミック

マグネシウムアルミネートスピネル

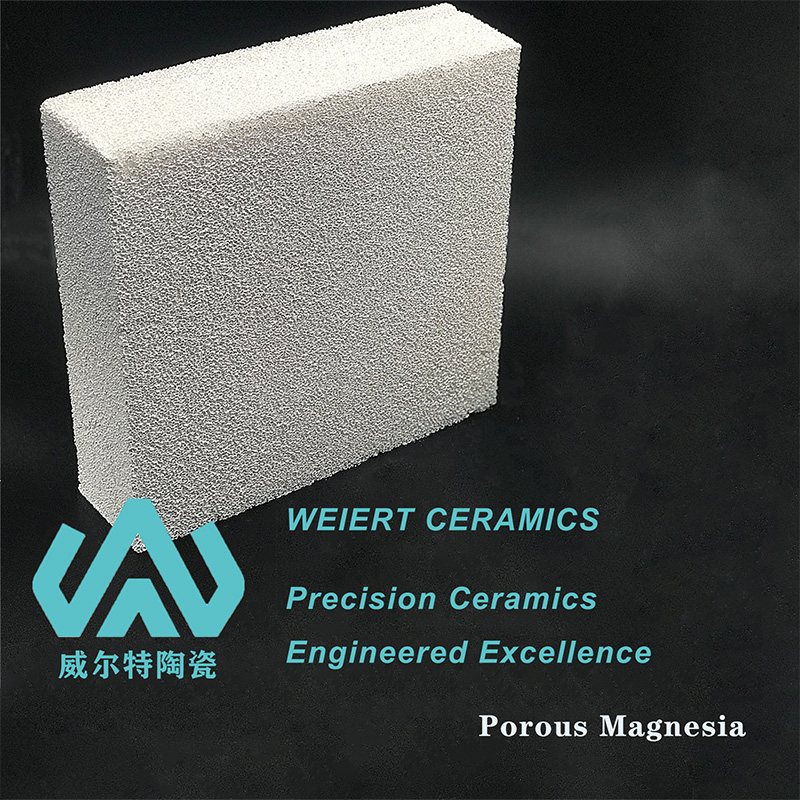

多孔質マグネシア・セラミックス

マグネシウムアルミネートスピネルセラミックは、化学式MgAl₂O₄で、るつぼに広く使用されている先進的なセラミック材料です。マグネシア(MgO)セラミックスと比較して、50%-70% Al₂O₃と酸化マグネシウムが共焼結されており、緻密でガラス化した構造となっています。この組成は、より高い耐熱衝撃性を提供し、マグネシウム合金やその他の反応性の高い合金の溶解に特に適しています。

かつてマグネシウム合金の鋳造には、炭素鋼やステンレス鋼などの鉄系るつぼが一般的に使用されていた。しかし、これらの材料は溶融金属やフラックスによる腐食の影響を非常に受けやすく、耐用年数が短い。黒鉛るつぼは、熱伝導率が高いものの、機械的強度が低く、不均一な加熱条件下では割れやすい。

マグネシウム合金は、その高い蒸気圧(例えば、727℃で1037Pa)により、ユニークな課題をもたらす。溶融マグネシウムとその蒸気は、多孔質セラミック材料に容易に浸透し、それらと反応して応力を発生させ、材料の劣化を引き起こします。その結果、構造的な損傷、材料の剥離、溶融合金の汚染が生じる。

マグネシウムアルミネートスピネルセラミックスの優れた特性マグネシウム合金は高い化学反応性を示し、Al₂O₃、ZrO₂、SiC、SiO₂などの従来のセラミック材料と反応することがあります。さらに、マグネシウムは溶融・精錬時に酸素、窒素、水蒸気と反応しやすく、酸化ロスや残留副生成物が生じます。これらの不純物は、マグネシウム合金製品の品質や性能に影響を与えます。マグネシウムアルミネートスピネルセラミック(MgAl₂O₄)は、これらの問題に効果的に対処します。緻密な微細構造と優れた耐酸化性により、溶融マグネシウムや蒸気の浸入を防ぎます。Al₂O₃の添加により焼結時の緻密化が促進され、構造的完全性がさらに向上します。その結果、この材料は、高純度の鉄およびその合金、ならびにニッケル、ウラン、トリウム、亜鉛、スズ、アルミニウム、およびそれらの合金の処理に最適です。

WEIERT Ceramics Technologyは、中国で最も優れたアルミン酸マグネシウムスピネルセラミックメーカーです。弊社はアルミン酸マグネシウムスピネルるつぼの生産者であるだけでなく、アルミン酸マグネシウムスピネルセラミック製品のカスタムサービスも提供しています。お気軽にお問い合わせください!

ポーラスセラミックスは、酸化マグネシウムを高温で焼結することにより、内部に多数の気孔を有する構造体を形成する材料である。多孔質マグネシアセラミックスは、マグネシウム含有量が95%を超える高純度の酸化マグネシウムを用いて製造される。一方、非多孔質または緻密な酸化マグネシウムセラミックス(気孔率0.1%未満)は、通常、他の成分の添加を必要とし、そのマグネシア含有量は通常60~80%の間である。

多孔質マグネシアセラミックスは、細孔の大きさによってミクロ孔とマクロ孔に分類されます。ミクロ孔は、触媒による浄化など、気体や液体を含む吸着・浄化プロセスに不可欠です。一方、マクロ孔は、フィルター洗浄システム、断熱材、生物医学用途で重要な役割を果たします。

について アプリケーション の マグネシセラミック :

マグネシア・セラミックスは、高温安定性と耐食性の両方でアルミナ・セラミックスを凌ぐ:

- るつぼと耐火物: 鉄鋼およびガラス製錬産業、特に腐食性条件下で使用される。

- 金属加工: ニッケル合金、放射性ウランおよびトリウム合金、鉄およびその合金などの金属および合金の溶解に適している。

- 原子力産業: 原子力用途の高純度ウランやトリウムの溶解に最適。

- 熱電対保護管: センサーの熱および化学的保護を提供。

- 電磁および光学部品: 電磁波を透過する性質があるため、レーダードームや赤外線投射窓に利用されている。

- 焼結サポート セラミックスの焼結キャリアとして機能し、特にβ-Al₂O₃のような腐食性・揮発性物質を高温で処理する。

- 圧電材料と超電導材料: 特殊用途の原料として使用され、耐鉛腐食性や非汚染性などの特性を持つ。

MgOセラミックスは、高温性能、化学的安定性、耐食性を兼ね備えているため、要求の厳しい工業用途や科学用途に不可欠です。

WEIERT Ceramics Technologyは中国で最高のMgOセラミック会社です。

マグネシアセラミック管、マグネシアセラミックリング、マグネシアブロック、および様々な複雑なマグネシアセラミック部品をカスタマイズして提供しています。