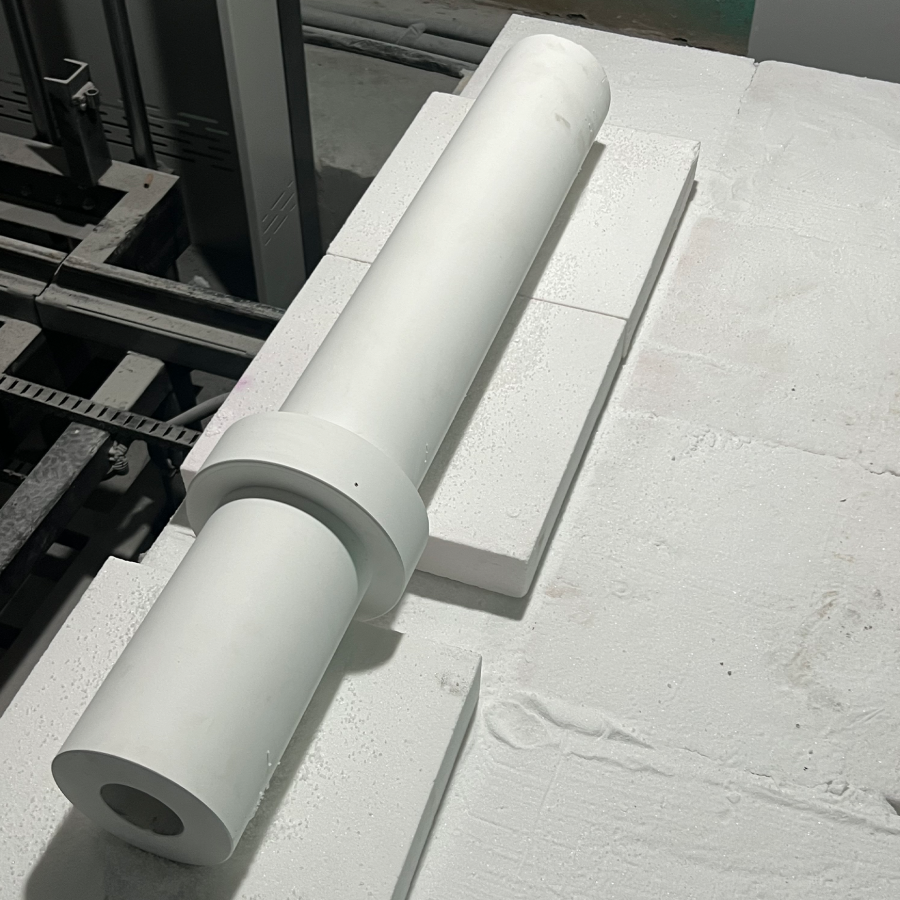

Large Alumina Tube

Product Name

Large Alumina Tube

Uses and Applications

Insulating ceramic tubes for large thermal cycling systems.

Product Specifications

| Product Description | Unità | Valore |

| Composition | 95% Al₂O₃ | |

| Dimensions | mm | ID = 42 , OD = 100, L = 700 |

| Tolerance Requirement | mm | ID:+2,OD:+1mm,L:+1 |

| Dielectric Breakdown Strength | kV | 42 |

| Pressure Resistance requirement | MPa | 2.5 |

| Temperature Resistance requirement | °C | 250 |

Acid Service Life :

The acid service life of this product can vary significantly depending on specific environmental conditions, including acid concentration, temperature, and exposure time. For detailed insights, please refer to the study by Ćurković et al. (2023), which investigates the corrosion kinetics of alumina ceramics in nitric acid under varying conditions:

Ćurković, L., Ropuš, I., Gabelica, I., & Rončević, S. (2023). Kinetics investigation of alumina ceramics corrosion in nitric acid. Advances in Applied Ceramics, 122(3–4), 129–136. https://doi.org/10.1080/17436753.2023.2230675

Product Advantages of this Alumina tube

Low cost

High insulation

Excellent corrosion resistance

Certifications and Standards

ISO 9001

Frequently Asked Questions (FAQ) about Alumina Ceramic Tube

Q1: How can the insulation of an alumina tube be improved while reducing its thickness or size?

A1: Using higher-purity alumina materials can enhance insulation, as higher purity increases both resistivity and dielectric strength. However, this also raises costs. Users need to weigh the trade-offs between cost and application requirements to make a comprehensive decision.

Q2: Is there a minimum order quantity (MOQ)requirement for ceramic components?

A2: No MOQ