Silicon Nitride Components Si3N4

Silicon Nitride Ceramic Components (Si₃N₄)

Silicon Nitride Ceramic Components (Si₃N₄)

Silicon nitride ceramics exhibit the best thermal shock resistance among all ceramic materials. Their thermal shock resistance is approximately 2.3 times greater than aluminum nitride ceramics, 2.7 times greater than zirconia ceramics, and an astonishing 4 times greater than alumina ceramics. This outstanding thermal shock resistance makes it highly suitable for components used in environments with rapid temperature changes or extreme thermal cycling.

However, in terms of hardness, silicon nitride ceramics are about 8% softer than alumina ceramics, 40% softer than aluminum nitride ceramics, but about 14% harder than zirconia ceramics. Despite being slightly softer, its high toughness, wear resistance, and thermal shock resistance make it an ideal material for many high-performance industrial applications.

1. Excellent Thermal Shock Resistance: Ideal for environments with rapid heating or cooling.

2. preventing cracks or failures caused by thermal stress.

3. High Toughness and Wear Resistance: Suitable for components that must endure mechanical impact or friction.

4. Good Chemical Stability: Suitable for corrosive environments or high-temperature chemical reaction equipment.

5. Lightweight: Ideal for industries like aerospace where weight is a critical factor.

Si3N4 Ceramic purity: >99%

Density: 3.22 g/cm³

Vickers Hardness(HV50): 15Gpa (1529) kg/mm²

Maximum Temperature: 1350℃(2462°F)

Thermal Conductivity @ RT: 29W/mK

Dielectric Strength: 300V/mil

Volume Resistivity @ 25°C : 10¹⁴Ω.cm

Applications of Silicon Nitride Ceramic Components:

1. Silicon nitride turbine rotors for turbochargers, designed to withstand high temperatures and 2.high-speed rotation.

2. Silicon nitride bearing components.

3. Silicon nitride turbine blades for aerospace engines.

4. Silicon nitride fuel cell separators.

5. Corrosion-resistant silicon nitride sealing rings for pump valve systems.

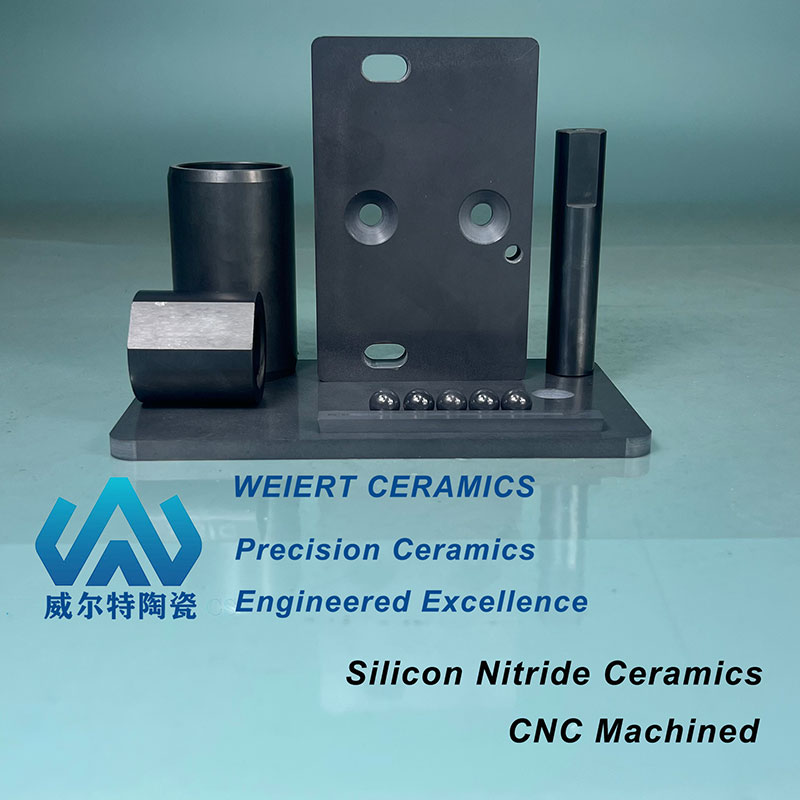

CNC Machined Silicon Nitride Ceramic Company

WEIERT Ceramics Technology specializes in CNC machining of silicon nitride ceramics, offering tailored solutions for machining silicon nitride ceramic components. We are dedicated to delivering high-quality, custom silicon nitride ceramic parts to meet the specific needs of our clients.

Custom Silicon Nitride Ring

Silicon Nitride Bearing Ball

Silicon Nitride Guide Rail

Silicon Nitride Plate

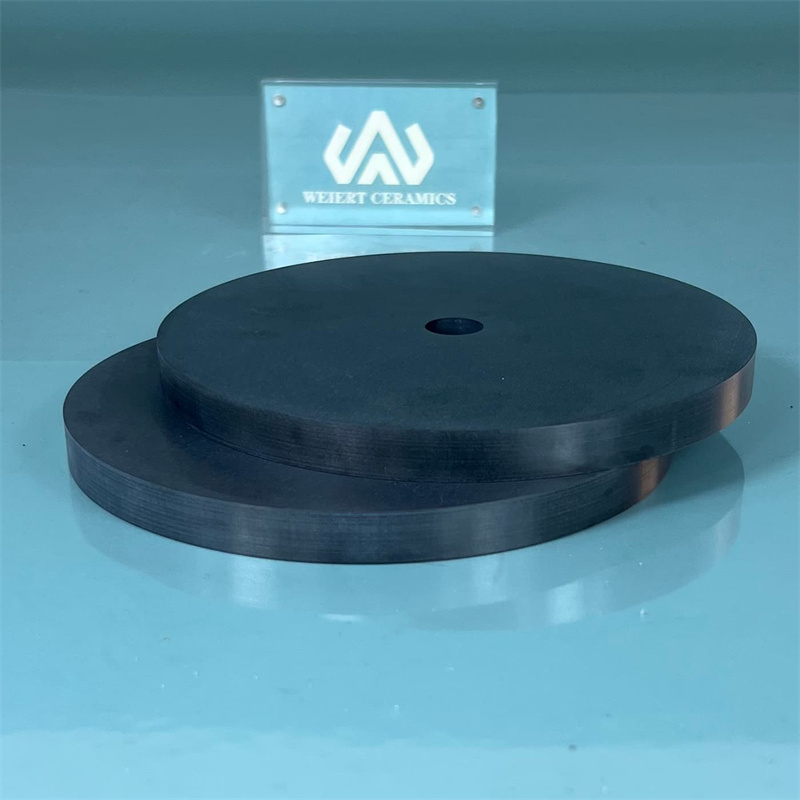

Silicon Nitride Disc