Magnesia Components, MgO

Magnesia Ceramic Components(MgO)

Magnesia Ceramic Components(MgO)

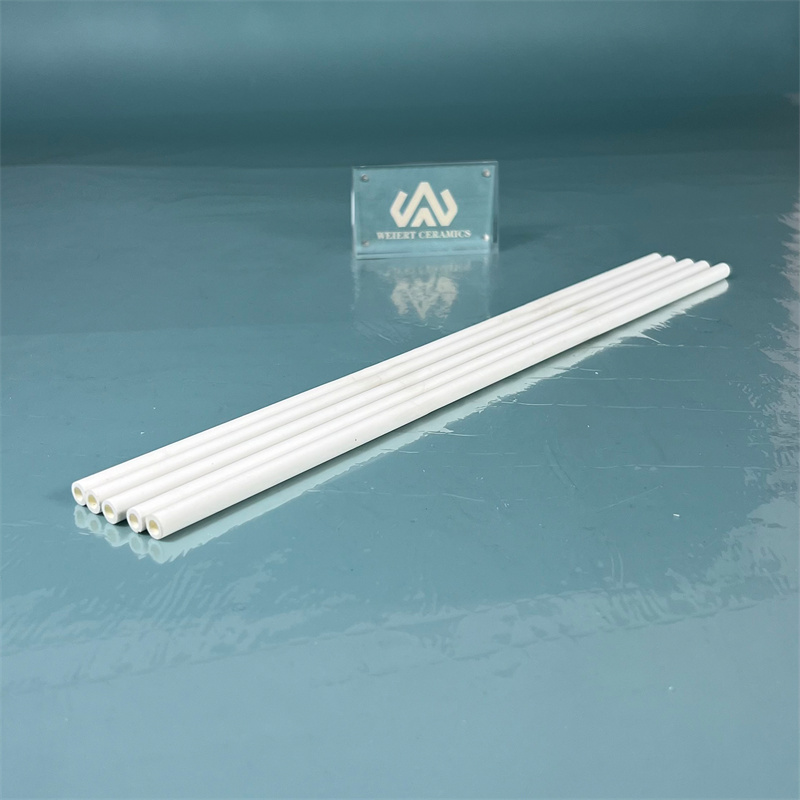

The main advantage of magnesium oxide ceramics is their excellent high-temperature performance. They can operate stably in environments exceeding 2000°C and exhibit relatively high chemical inertness at high temperatures. Therefore, magnesium oxide ceramic components are commonly used as support components in high-temperature environments or as heating tubes in high-temperature furnaces.

Additionally, magnesium oxide ceramics have broad application prospects in industries such as metal smelting. However, a key challenge is improving their thermal shock resistance. In practical applications, such as magnesium oxide crucibles, a longer preheating time is often required to prevent cracks caused by thermal stress.

High-temperature insulators, heating elements, and thermocouple protection tubes.

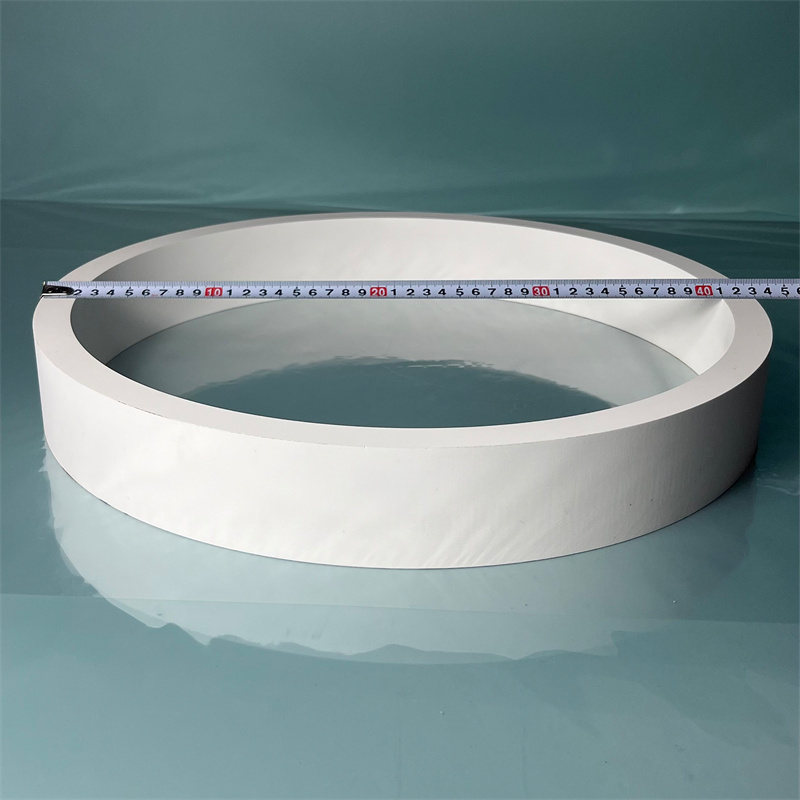

Crucibles, casting molds, refractory linings, and saggers.

Insulating materials and thermal shielding in nuclear reactors.

MgO Ceramic purity:99.7%

Density:3.4g/cm³

Water Absorption:6.5%

CTE (20-1000°C): 13 x 10^-6/K^-1

Specific heat capacity:0.900J/g-°C

Therm. Conductivity (400°C): 44W/m-K

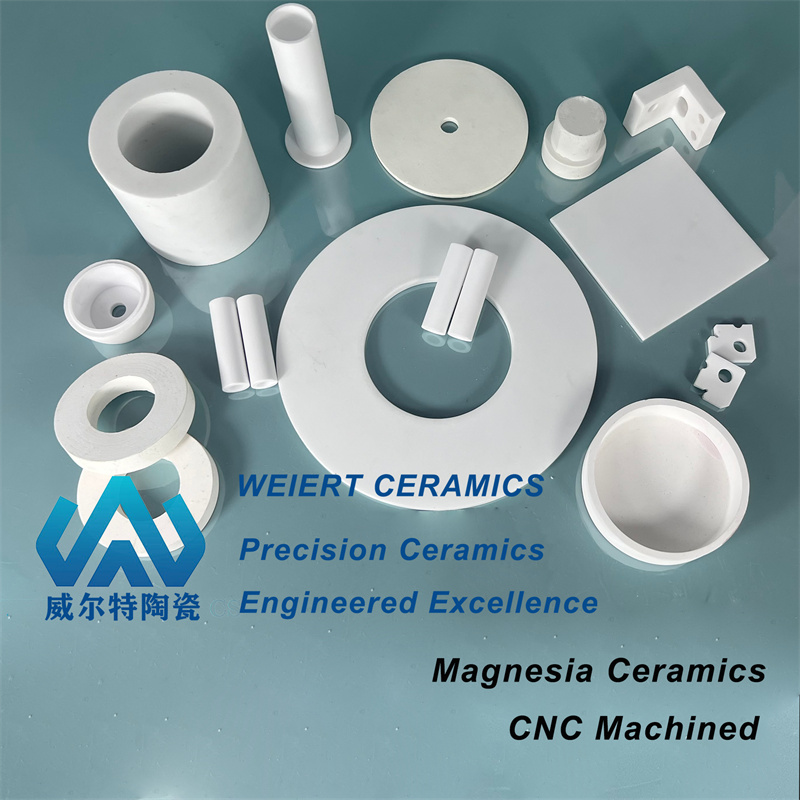

Magnesia Ceramic Company

WEIERT Ceramics is an original Magnesia ceramic company specializing in the development, production, and supply of Magnesia ceramic products. Our main offerings include custom Magnesia crucibles, custom Magnesia ceramic rods, and magnesium oxide ceramic tubes etc.To address the need for better thermal shock resistance in magnesium oxide ceramics, the WEIERT research team is actively exploring innovative solutions aimed at improving their reliability and durability in high-temperature environments.