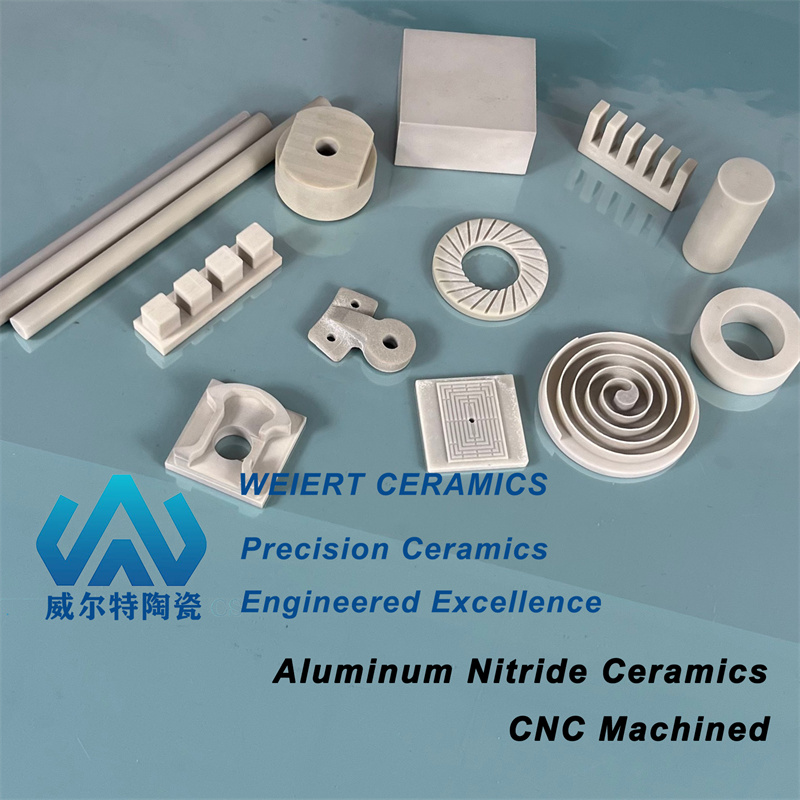

Aluminum Nitride Components AIN

Aluminum Nitride (AlN) Ceramic Parts

Aluminum Nitride (AlN) Ceramic Parts

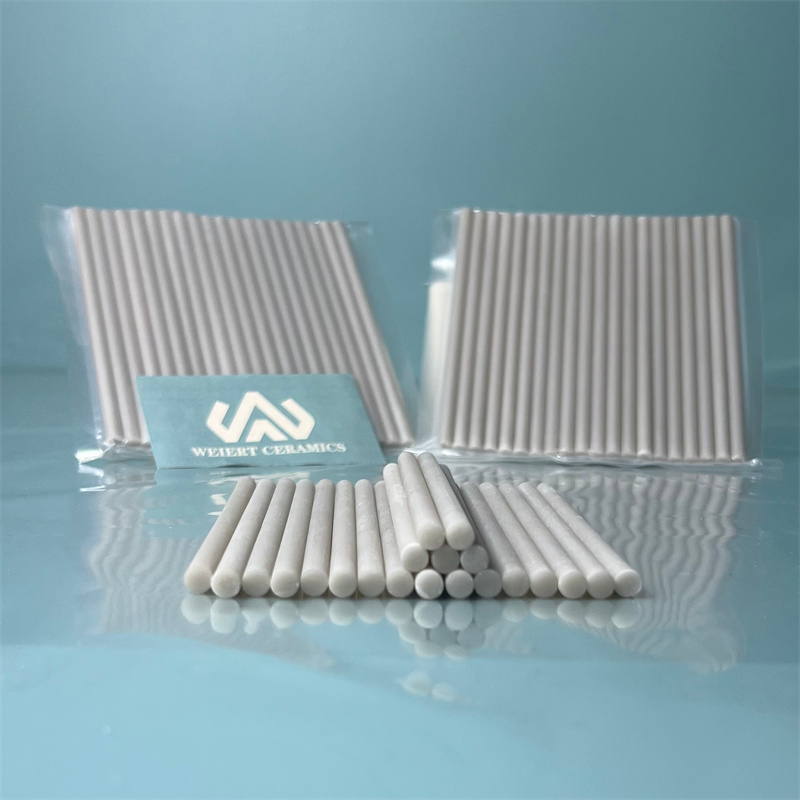

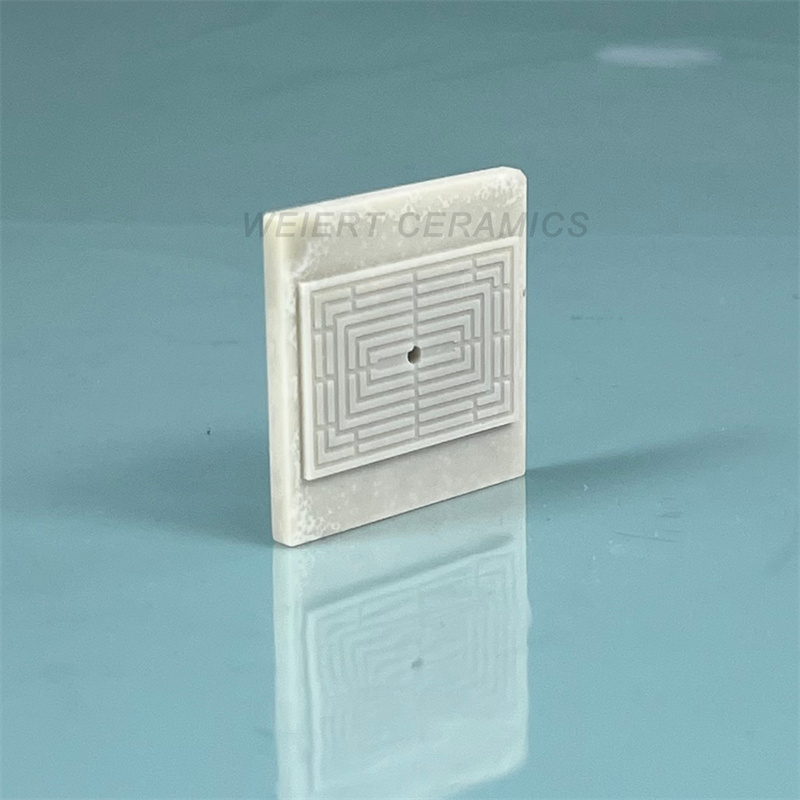

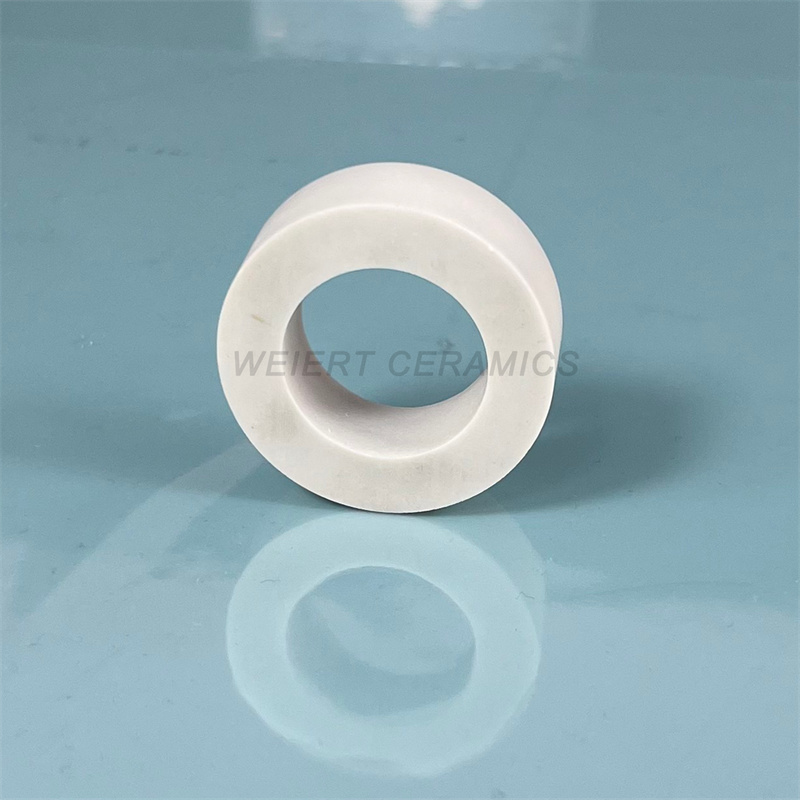

When selecting aluminum nitride ceramics for components, the operational conditions usually require specific thermal conductivity and expansion coefficient properties. Due to its excellent thermal conductivity and electrical insulation properties, aluminum nitride ceramics are often used to manufacture electronic heat dissipation components. We can perform high-precision CNC machining based on the product drawings you provide.

If you’re uncertain whether AlN ceramics are suitable for manufacturing your ceramic components, please refer to the following information:

The thermal conductivity of aluminum nitride ceramics is close to that of silicon carbide (approximately 25% lower than silicon carbide). It also has a relatively low thermal expansion coefficient compared to other ceramic materials. Its electrical insulation properties are similar to other functional ceramics.

(Silicon carbide ceramics have the highest thermal conductivity among all ceramic materials, around 210 W/m·K.)

The thermal expansion coefficient of aluminum nitride ceramics is 64.3% higher than that of silicon nitride.

The thermal expansion coefficient of aluminum nitride ceramics is 24.3% higher than that of silicon carbide.

The thermal expansion coefficient of aluminum nitride ceramics is 56.2% lower than that of zirconia.

The thermal expansion coefficient of aluminum nitride ceramics is 36.1% lower than that of yttria.

AlN Uses

Aluminum nitride ceramics are widely used in fields such as electronics, semiconductors, optoelectronics, aerospace, automotive, medical, industrial equipment, and communications, primarily for critical components like heat dissipation substrates, packaging materials, heaters, and thermal management modules.

AlN Company

WEIERT Ceramics Technology specializes in CNC machining of AlN ceramics, offering tailored solutions for machining AlN ceramic components. We are dedicated to delivering high-quality, custom AlN ceramic parts and AlN crucibles to meet the specific needs of our clients.

AlN Ceramic purity:99.4%

Density: 3.33 g/cm³

Thermal Conductivity @ 20°C: 175W/mK

CTE, linear (20-1000°C):5.6 x 10-6/℃

Maximum Temperature: 800℃

Dielectric Strength: ≥13.3KV/mm

Volume Resistivity @Th 1.50 mm : 1013Ω.cm

Hardness @20℃: 1100-1200