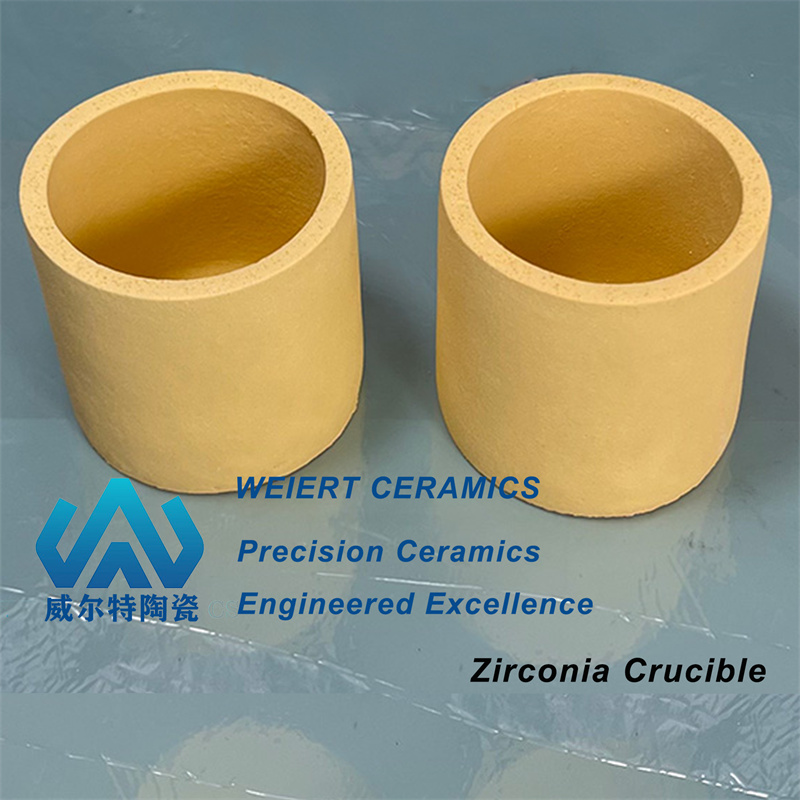

Zirconia Crucible, Composite ZrO2

Intruduction to Zirconia Crucibles

Intruduction to Zirconia Crucibles

Pure zirconia (ZrO2) has an extremely high melting point of up to 2760°C and exhibits excellent chemical inertness to most commonly used casting alloys. A study has shown that ZrO2 may still be reduced by the active element hafnium (Hf) in high-temperature alloys(Valenza, Muolo, & Passerone, 2010).

WEIERT’s zirconia crucibles are made from Composite Stabilized Zirconia. Thanks to the unique physical properties imparted by Composite Stabilized Zirconia, these crucibles offer exceptional thermal shock resistance, allowing them to withstand repeated and severe temperature fluctuations without significant structural damage. This helps reduce furnace downtime for maintenance and increases casting yield.

The maximum operating temperature for these zirconia melting crucibles can reach up to 2200°C, providing higher melt cleanliness at high temperatures, which minimizes crucible contamination and impurities in molten metals. Additionally, they have a long service life and superior performance compared to crucibles made from other materials.

Applications:

- Vacuum investment casting

- Alloy melting crucibles

- Precious metal melting crucibles

- Glass melting crucibles

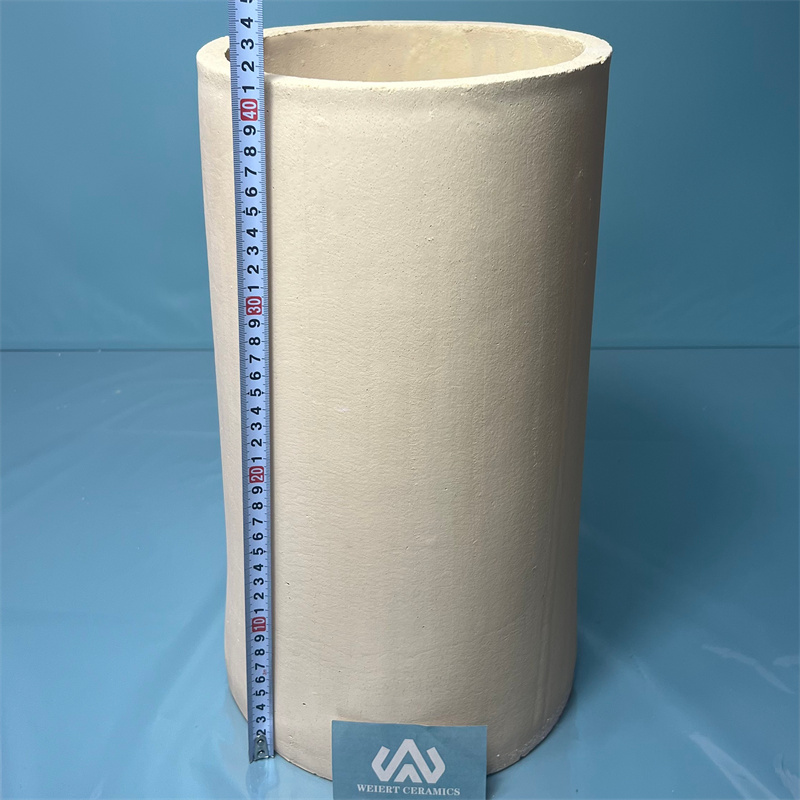

Available maximum size: H 400mm x OD 300mm x Th 10mm, volume 24L

Available minimum size: H 10mm x OD 10mm x Th 2mm, volume 0.00026L

FAQ

Q1:What is the minimum order quantity (MOQ) for your crucibles?

A1:Our minimum order quantity (MOQ) is just 1 piece, allowing you to order even a single unit for your needs.

Q2:Can I customize the size of the zirconia crucibles?

A2:Yes, we offer customization for zirconia crucibles. You can specify the dimensions that suit your requirements, and we’ll produce them to meet your needs.

Q3:Are your zirconia crucibles resistant to thermal shock?

A3:zirconia crucibles offer good thermal shock resistance compared to other materials.

Zirconia Crucible China Manufacture.

Contact us today to discover how our high-performance zirconia crucibles can enhance your production process! Simply send us your drawings and specify the quantity you need, and we will provide you with a prompt quote.

Valenza, F., Muolo, M.L. and Passerone, A. (2010) Wetting and Interactions of Ni- and Co-Based Superalloys with Different Ceramic Materials. Journal of Materials Science, 45, 2071-2079.

https://doi.org/10.1007/s10853-009-3801-4