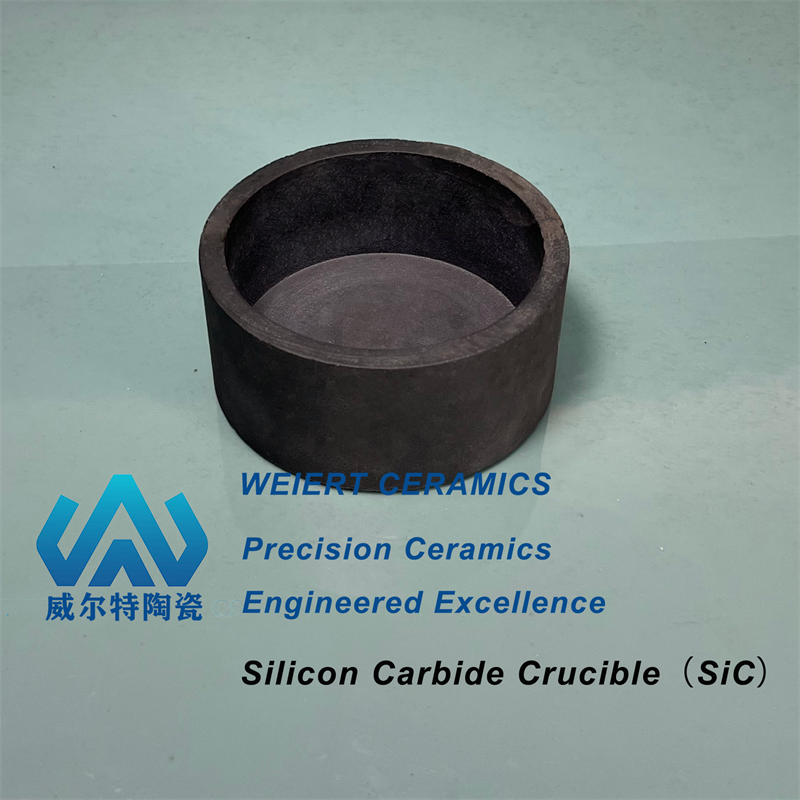

Silicon Carbide Crucible,SiC

Silicon Carbide Crucible Introduction

Silicon Carbide Crucible Introduction

Silicon carbide crucibles are made from silicon carbide material through isostatic pressing and pressureless sintering. They can be manufactured in various shapes, including round and square crucibles, with flat, semi-flat, or spherical bottoms. Additional processing options include flanges and drilling. Due to the submicron fine-grained structure and production process, the product surface is smooth, with a roughness of Ra<1.6 in the raw state, helping to minimize liquid erosion.

Performance Advantages:

1.High Purity: Contains more than 99% SiC, ensuring controlled material contamination.

2.High-Temperature Resistance: Stable thermal properties allow operation up to 1700℃ in air or 1950℃ in nitrogen or argon atmospheres.

3.Mechanical Properties: High strength and hardness provide wear resistance and permeability control at 1250℃ under high temperature and pressure conditions, allowing high-speed medium flow.

4.Thermal Conductivity: Significantly higher than other corrosion-resistant materials.

5.Corrosion Resistance: Resistant to strong acids, bases, oxidizers, and mixed acids such as sulfuric acid, nitric acid, and phosphoric acid, ensuring long-term durability.

6.Thermal Shock Resistance: Due to high thermal conductivity and stability, silicon carbide crucibles adapt to rapid temperature changes in various processes.

Performance specifications table for SiC Crucible

| Property | Value | Unit |

| Alkali Resistance | – | – |

| Mohs Hardness | 13 | – |

| Coeffcient of Thermal Expansion | 4.5 | K-1×10-8 |

| Thermal Conductivity | 45(1200°C),300(20°C) | W/m·K |

| Modulus of Elasticity | 280(1200°C),330(20°C) | GPa |

| Bending Strength | 250(1200°C),280(20°C) | MPa |

| Density | 3.02 | g/m³ |

| Porosity | ≤0.1 | % |

| Max Temperature of Application | 1380 | ℃ |

Specifications and Models:

Silicon carbide crucibles are custom-manufactured based on customer requirements.

Applications:

1.High-Temperature Processing: Ceramic powder sintering, molten salts, and reactions involving strong acids, bases, and oxidizers, as well as non-ferrous metal melting.

2.Chemical and Metallurgical Processes: Used in pharmaceuticals, fine chemicals, metallurgy, acid pickling, and lithium battery material sintering. Suitable for environments with exposure to sulfuric acid, nitric acid, hydrochloric acid, sodium hydroxide, halogenated compounds, and organic solutions.

3.Typical Customers: Pharmaceutical companies, sulfuric acid plants, and petroleum processing lines.

4.Heat Exchangers: Used in silicon carbide saggars, crucibles, corrosion-resistant saggars, and high-temperature crucibles.