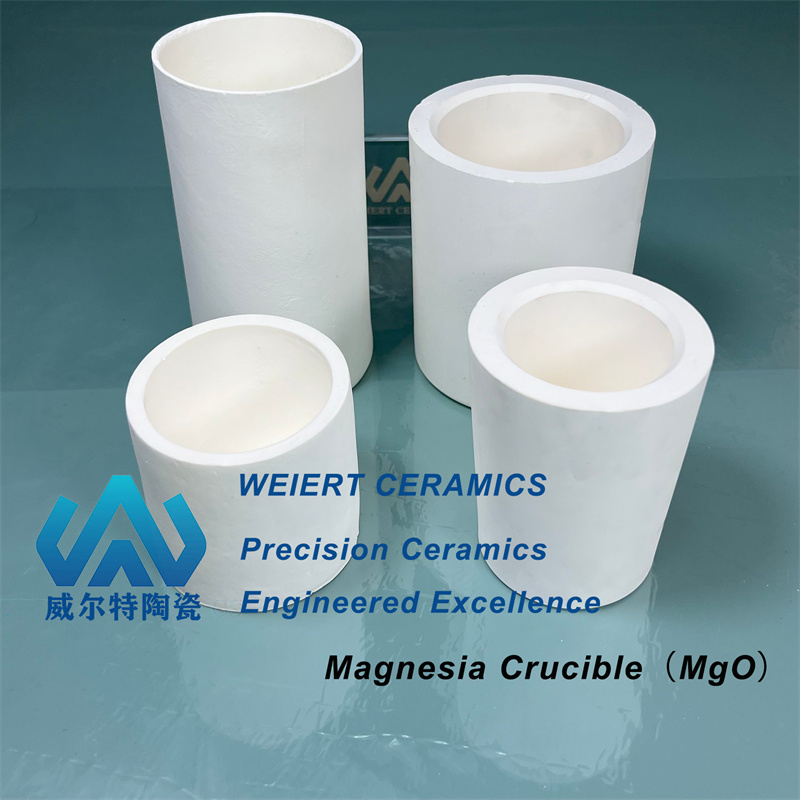

Magnesia Crucible, MgO

Product Name:

Product Name:

Magnesium Oxide Crucible

Introduction to Magnesium Oxide Crucibles:

The primary material of magnesium oxide ceramic crucibles is MgO (magnesium oxide). Yttrium oxide can be added as a stabilizer to enhance chemical stability, depending on specific requirements.

These crucibles are mainly used for alloy melting in induction furnaces.

Chemical Composition of Magnesium Oxide Crucibles:

| Chemical component |

Value |

|

MgO |

≥ 99.7% |

|

CaO |

≤ 0.002% |

|

Fe |

≤ 0.002% |

|

Mn |

≤ 0.003% |

|

SiO₂ |

≤ 0.08% |

|

Al |

≤ 0.09% |

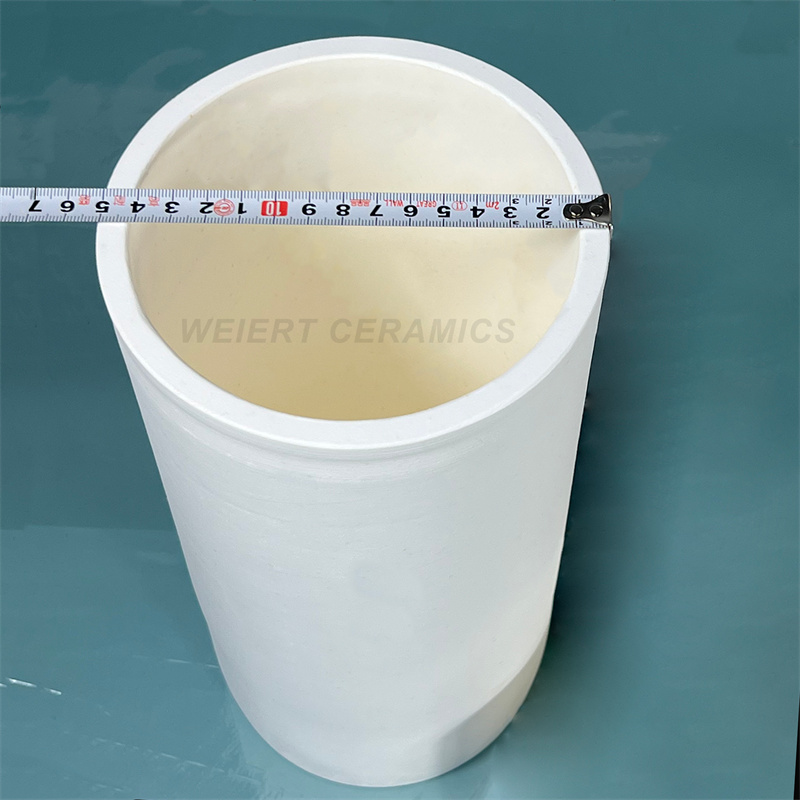

Available Sizes of Magnesium Oxide Crucibles:

Minimum Size: H3.1mm x OD2.6mm x ID2.1mm

Minimum Volume: 0.0057 ml

Maximum Size: H400mm x OD300mm x ID280mm

Maximum Volume: 3644.25 ml

Advantages of Magnesium Oxide Crucibles:

The maximum operating temperature can reach up to 2200°C under specific conditions. (Note: Excessive temperatures during alloy melting may cause oxygen and aluminum contamination in the melt.)

Applications of Magnesium Oxide Crucibles:

Oxide refractory materials for induction melting crucibles mainly include MgO and Al₂O₃. In certain applications, MgO crucibles can replace Al₂O₃ crucibles.

By controlling refining temperature and time, high-quality high-temperature alloy ingots can be produced.

Melting tire cord steel

Melting AerMet100 steel (under 50-100 Pa vacuum)

Melting plutonium, uranium, and nickel-based alloys

FAQ:

Q1. What chemical reactions occur in Magnesia (MgO) crucibles under high vacuum and high-temperature conditions?

A1. As the vacuum level and refining temperature increase, Magnesia (MgO) crucibles tend to decompose free oxygen, which is then introduced into the molten steel.

Q2. What is the optimal storage environment for magnesium oxide ceramics?

A2. Magnesia (MgO) ceramics are highly susceptible to moisture and hydrolysis; therefore, they require a dry storage environment.

Q3. How can thermal cracking in magnesia (MgO) crucibles be prevented?

A3. Magnesia (MgO) crucibles are sensitive to thermal shock and require uniform heating. It is recommended to increase the temperature by no more than 200°C per hour.

The Cheapest Magnesia (MgO) Crucible Supplier in China

At WEIERT CERAMICS, we are dedicated to providing our customers with the most cost-effective magnesium oxide crucibles. By continuously exploring ways to reduce crucible usage costs, we aim to help our clients significantly lower their metal refining expenses.