Alumina Crucible Al2O3

Product Name

Product Name

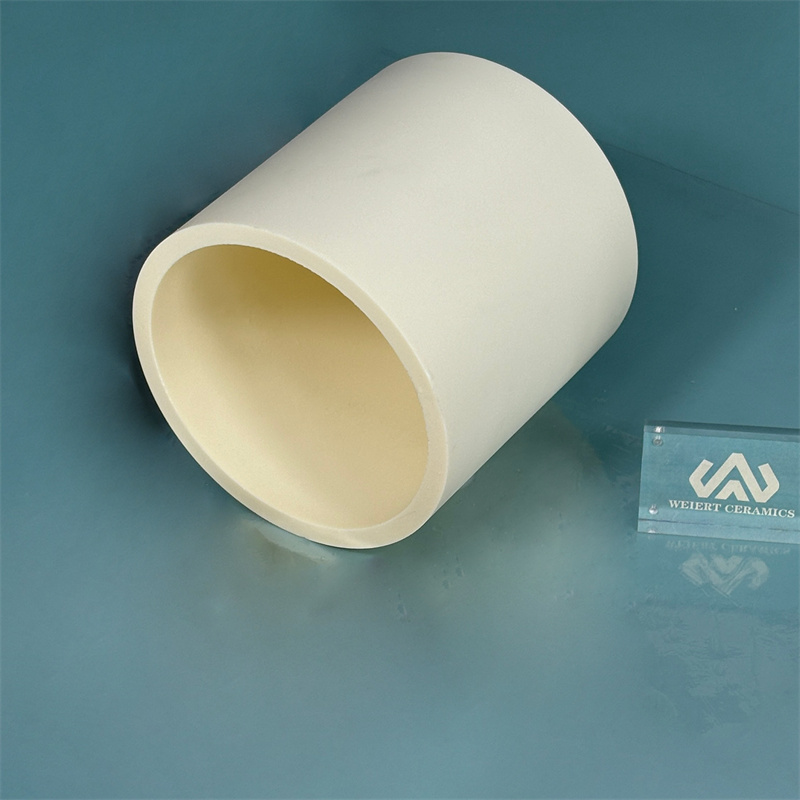

High-Purity Alumina Crucible (Al2O3)

Introduction to High-Purity Alumina Ceramic Crucible

The purity of High-Purity alumina material typically ranges from 95% to 99.7%.。Alumina crucibles are widely used in industrial production and laboratory environments. They are among the most commonly used ceramic crucibles due to their mature technology, well-balanced properties, and relatively economical cost. Alumina crucibles are suitable for use in medium- and high-frequency induction furnaces, electric furnaces, and vacuum furnaces, where they serve as heating containers.

In high-end metallurgy, alumina crucibles are often used as liners. To achieve higher purity in molten metals and prevent contamination caused by direct contact with alumina, high-purity alumina is required for crucible manufacturing. In some cases, additional plasma spraying is necessary. For example, when melting titanium alloys, a Y2O3 coating is applied to the inner surface of the crucible.

One of the main drawbacks of ceramic crucibles is their relatively low thermal shock resistance, which limits their lifespan and the number of uses.

Available Types of Alumina Crucible

1. Shapes of Al2O3 Crucible:

Cylindrical Alumina Crucible (Standard Type)

Conical Alumina Crucible (Easy-Pouring Type)

Flat Alumina Crucible (Large Surface Area Type)

Rectangular Alumina Crucible

Boat-Shaped Alumina Crucible

Flanged Alumina Crucible

Custom Alumina Crucible (Can be customized according to customer requirements)

2.Sizes of Al2O3 Crucible:

Smallest Size Alumina Crucible: 0.063 mL (OD 5 mm × H 5 mm × Th 0.5 mm)

Largest Size Alumina Crucible: 72,380 mL (OD 500 mm × H 400 mm × Th 10 mm)

Custom Sizes: Available upon request

Technical Parameters of Alumina Crucibles:

1.Material Specifications:

Four purity levels of Alumina Content: ≧95% Al2O3,≧99% Al2O3,≧99.7% Al2O3, ≧99.99%

Four purity levels of Alumina density: 3.72g/cm³ ,3.9g/cm³, 3.92g/cm³ , 3.98g/cm³

2.Performance Features:

Four purity levels of Alumina C.T.E. 25°-600°C :

7.7× 10⁻⁶ /°C, 7.6× 10⁻⁶ /°C 8.0× 10⁻⁶ /°C 8.1× 10⁻⁶ /°C

Maximum Operating Temperature: 1650℃

Applications of High Purity Alumina Crucibles:

Chemical analysis experiments

Semiconductor material processing

Precision casting

Rare earth material processing

Special alloy smelting

Material evaporation in PVD processes

Quality Certification:

ISO 9001 Quality Management System Certification.

Crucible Cleaning Steps:

- Soak in 0.1M KOH solution for 15-20 min.

- Rinse thoroughly with deionized water.

- Ultrasonic clean for 60 min using fine powder detergent (2 tbsp in 200 mL water).

- Rinse again with deionized water.

- Soak in acetone and ultrasonically clean for 20 min.

- Repeat with isopropanol for another 20 min.

- Dry at 70°C for 40+ min.Or high-temperature heating can burn off organic residues.

Advantages of Al2O3 Crucibles Produced by WEIERT Ceramic

10 years of advanced ceramic experience: We are more professional in the field of ceramic Crucible materials.

Commitment to process innovation: Maximizing cost reduction to provide customers with competitive prices.

Ultra-high purity of materials: Ensuring the quality of our crucibles.

Precise dimensional tolerance control: ≤ ±0.1mm.

Surface roughness: Ra ≤ 1.6μm.