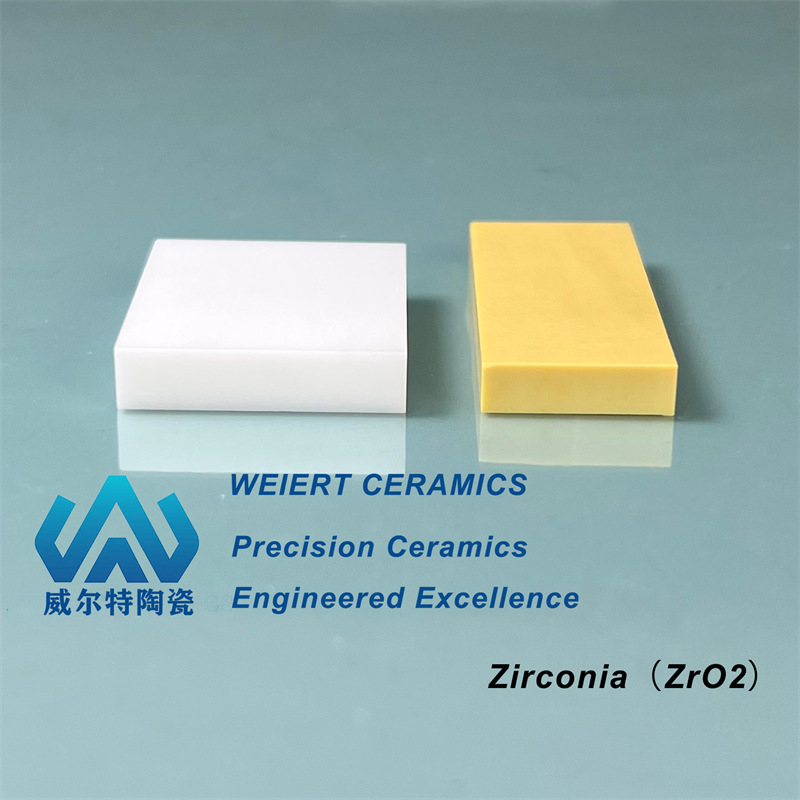

Zirconia Ceramic (ZrO2)

Zirconia ceramic is a type of technical ceramic widely used in industrial applications. It’s typically not made from pure zirconia but rather from zirconia mixed with stabilizers like CaO, MgO, CeO₂, or Y₂O₃ during the sintering process. These stabilizers give zirconia ceramics different properties. For instance, yttria-stabilized zirconia (YSZ) has a theoretical operating temperature of around 500°C (in practice, it’s often lower), while magnesia-stabilized zirconia (MSZ) can withstand temperatures exceeding 2200°C when processed with specialized techniques.

Zirconia ceramic is a type of technical ceramic widely used in industrial applications. It’s typically not made from pure zirconia but rather from zirconia mixed with stabilizers like CaO, MgO, CeO₂, or Y₂O₃ during the sintering process. These stabilizers give zirconia ceramics different properties. For instance, yttria-stabilized zirconia (YSZ) has a theoretical operating temperature of around 500°C (in practice, it’s often lower), while magnesia-stabilized zirconia (MSZ) can withstand temperatures exceeding 2200°C when processed with specialized techniques.

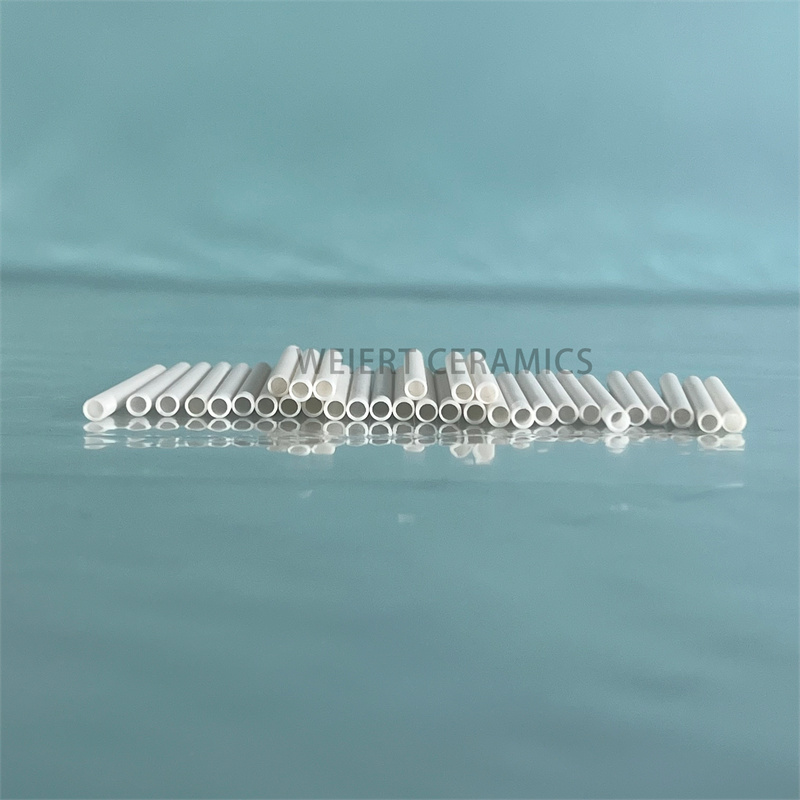

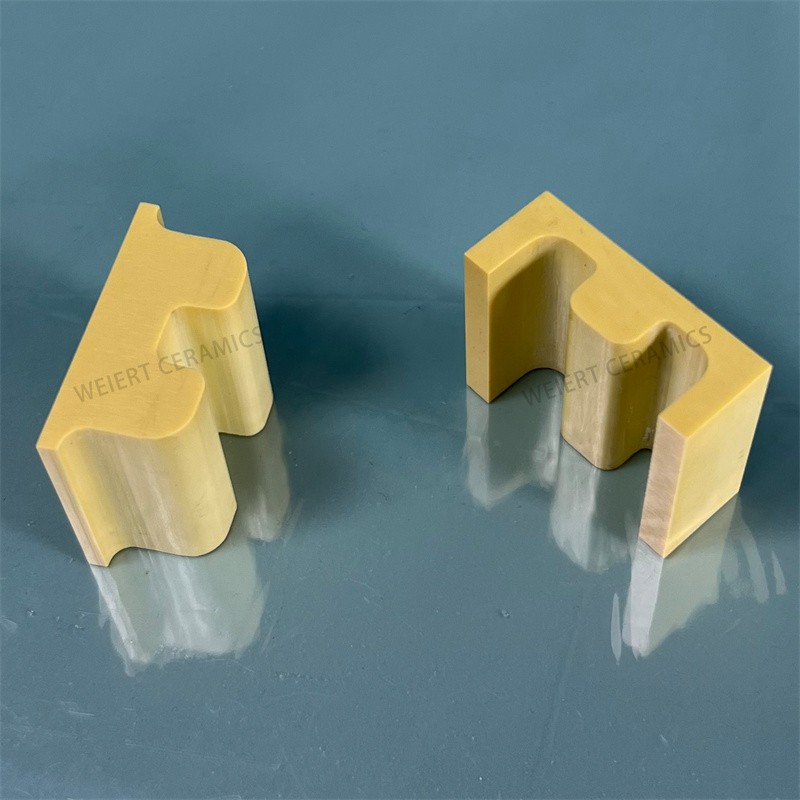

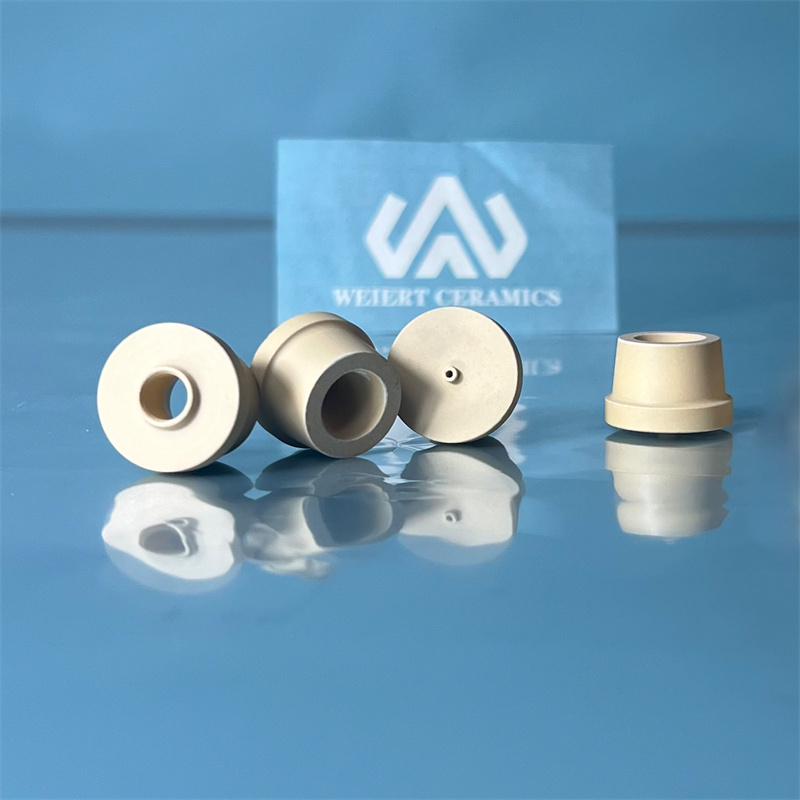

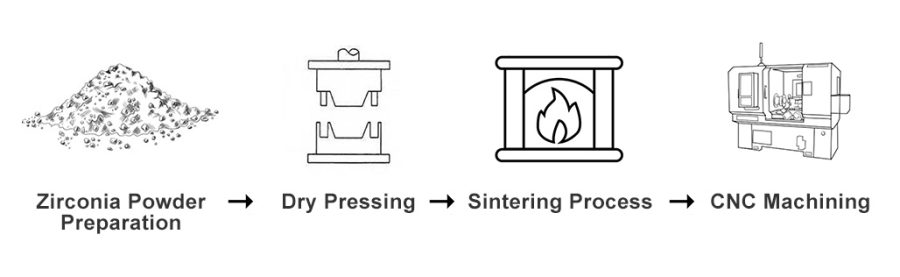

The manufacturing process for zirconia ceramics involves powder forming, high-temperature sintering, and CNC machining. Beyond the usual benefits of ceramics like wear resistance and corrosion resistance, zirconia ceramics stand out for their exceptional fracture toughness, making them easier to machine compared to most other ceramics.

Features

- High surface finish

- High density

- Superior toughness

- Corrosion resistance

- High-temperature resistance

- Wear resistance

- High elastic modulus

Zirconia Ceramic Property Chart

| General | Unit | YSZ | MSZ |

| Colour | white | yellow | |

| Density | g/cm³ | 6.02 | 5.75 |

| Water Absorption | % | 0 | 0 |

| Gas Permeability | atms-cc/sec | gas tight <10⁻¹º | gas tight <10⁻¹º |

| Mechanical Properties | Unit | YSZ | MSZ |

| Vickers Hardness (500 gm) | GPa (kg/mm² ) | 12.5 (1250) | 11.7 (1200) |

| Rockwell Hardness | R45N | 80 | 78 |

| Compressive Strength @ 25°C | MPa (psi x 10³) | 2485 (360) | 1862 (270) |

| Flexural Strength (MOR) (3 point) @ 25°C |

MPa (psi x 10³) | 951 (138) | 586 (85) |

| Fracture Toughness (Notched Beam) |

MPa·m^1/2

|

10 | 12 |

| Modulus of Elasticity | GPa (psi x 10⁶) | 210 (30) | 206 (29.8) |

| Poisson’s Ratio | 0.30 | 0.28 | |

| Tensile Modulus @ 25°C | MPa (psi x 10³) | 550 (80) | 310 (45) |

| Thermal Properties | Unit | YSZ | MSZ |

| Thermal Conductivity @ 25°C | W/m-K | 2.2 | 3 |

| Specific Heat Capacity | J/g-°C | <= 0.600 | 0.500 |

| C.T.E. 25 – 100°C | x 10⁻⁶/°C | 6.9 | 8.9 |

| C.T.E. 25°-300°C | x 10⁻⁶/°C | 8.1 | 9.7 |

| C.T.E. 25°-600°C | x 10⁻⁶/°C | 10.5 | 10.0 |

| Max.Service Temp.(Air) | Fahrenheit (°F) | 572 | 3992 |

| Max.Service Temp.(Air) | Celsius (°C) | 300 | 2200 |

| Electrical Properties | Unit | YSZ | MSZ |

| Dielectric Constant @ 1 MHz | 30 | 22.7 | |

| Dielectric Constant @ Gigahertz | 6.2 | ||

| Dielectric Loss @ 1 MHz | 0.0018 | ||

| Dielectric Loss @ Gigahertz | 6.2 | ||

| Dielectric Strength (0.125” Thick) | V/mil | 240 | 300 |

| Volume Resistivity @ 25°C | ohms-cm | > 1 x 10¹³ | > 1 x 10¹³ |

| Volume Resistivity @ 300°C | ohms-cm | 1 x 10¹º | 5 x 10⁷ |

| Volume Resistivity @ 500°C | ohms-cm | 1 x 10⁶ | 1 x 10⁷ |

| Volume Resistivity @ 700°C | ohms-cm | 5 x 10³ | 2 x 10⁶ |

*The values represent typical material properties and may vary depending on product configuration and the manufacturing process, For further information, do not hesitate to contact us.

Applications

Yttria-stabilized zirconia (YSZ):

- Corrosion-resistant fittings

- Wear-resistant parts

- Dental implants and joint replacements

- Small, high-precision components

- Decorative ceramics

Magnesia-stabilized zirconia (MSZ):

- Primarily used in high-temperature environments

Three Types of Zirconia Composite Ceramics

Yttria-Stabilized Zirconia (YSZ)

Yttria-Stabilized Zirconia (YSZ) Magnesia-StabilizedZirconia (MSZ)

Magnesia-StabilizedZirconia (MSZ) Zirconia-Toughened Alumina (ZTA)

Zirconia-Toughened Alumina (ZTA)

Black Zirconia

Fully stabilized zirconia ceramics are made from pure zirconia without the addition of stabilizers and are sintered at temperatures reaching 2000°C, resulting in a transparent appearance, also known as transparent zirconia, with a cubic crystal structure. Partially stabilized zirconia refers to zirconia ceramics sintered with stabilizers such as yttria, magnesia, or calcia, featuring a crystal structure that consists of a coexistence of monoclinic and tetragonal phases.

Mg-PSZ (Magnesia-Partially Stabilized Zirconia)

This Ceramic material is partially stabilized by adding a small amount of magnesia (MgO), resulting in a mix of tetragonal, monoclinic, and cubic phases.

The features of Mg-PSZ Ceramic

The tetragonal phase can transform into a monoclinic phase under stress, a process called transformation toughening, which enhances toughness.

Mg-PSZ exhibits high strength and offer extra fracture resistance.

MSZ (Magnesia-Stabilized Zirconia)

MSZ is created by adding a higher amount of magnesia, which fully stabilizes zirconia into a cubic phase. This prevents phase transformations at relatively low temperatures, resulting in greater stability.

The Features of MSZ Ceramic

Predominantly cubic phase, with minimal to no monoclinic or tetragonal phases.

Lacks transformation toughening but offers exceptional high-temperature stability and resistance to chemical corrosion.

Lower toughness but excels in high-temperature and chemical-resistant applications.

Electric fused zirconia ceramics are made using an electric fusion process, resulting in highly controlled grain sizes. These ceramics are specifically designed for environments with significant temperature variations.

They can withstand temperatures up to 2500°C and offer exceptional thermal shock resistance. Even under rapid heating conditions, such as 25°C to 1500°C, the material remains undamaged.

This makes electric fused zirconia an ideal material for crucibles, significantly reducing preheating time and improving production efficiency while minimizing the risk of cracking during use.

Zirconia Toughened Alumina (ZTA) combines an alumina (Al₂O₃) matrix with zirconia (ZrO₂) as the toughening phase. When ZrO₂ particles undergo phase transformation, they expand, creating compressive stress at the crack tips. This compressive stress prevents crack propagation and significantly improves the material’s toughness.

ZTA ceramics are widely used in applications requiring high strength, durability, and fracture resistance.

Zirconia Ceramic processing and Machining

WEIERT CERAMICS is the best zirconia ceramic manufacturer in China, specializing in developing industrial ceramic materials and precision CNC machining of zirconia components.

Our Zirconia Ceramics Services

WEIERT CERAMICS: Your Professional Zirconia Ceramic Supplier. With over 10 years of experience in technical ceramics manufacturing, we offer both standard and custom high-precision zirconia rods, tubes, plates, components, and crucibles.