Alumina Ceramic(Al2O3 )

Alumina Ceramics (Al₂O₃) and corundum.

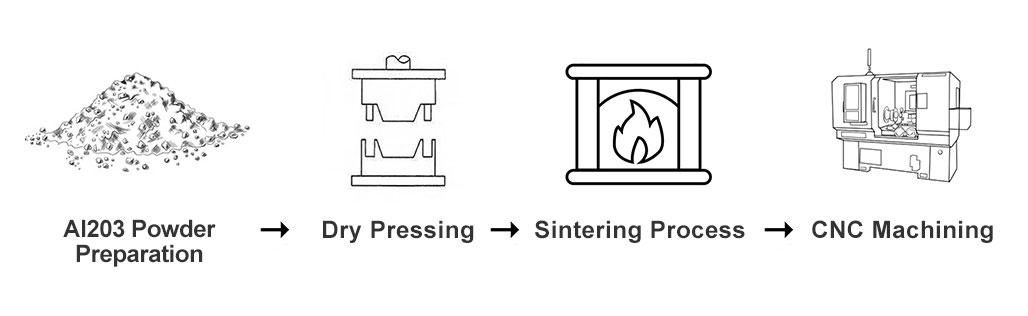

Alumina ceramics (Al₂O₃), are a key member of advanced ceramics family, made from high-purity synthetic alumina powder. The process involves molding the powder into green bodies with pressure-forming equipment, followed by high-temperature sintering. For high-precision components, CNC machining is often used before or after sintering.

With the rise of 3D printing, alumina photopolymerization has become an important shaping method as well.

Alumina ceramics come in various forms based on crystal structure, mainly including α-Al₂O₃, β-Al₂O₃, and γ-Al₂O₃. After high-temperature sintering (typically over 1200°C), all structures transform into α-Al₂O₃, also called corundum.

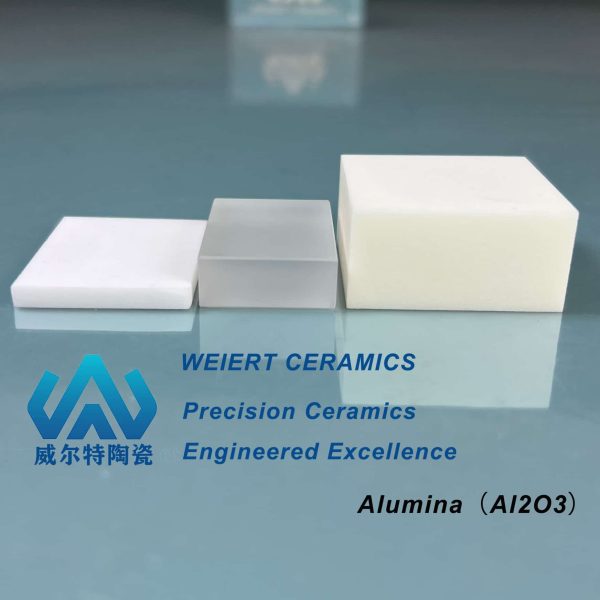

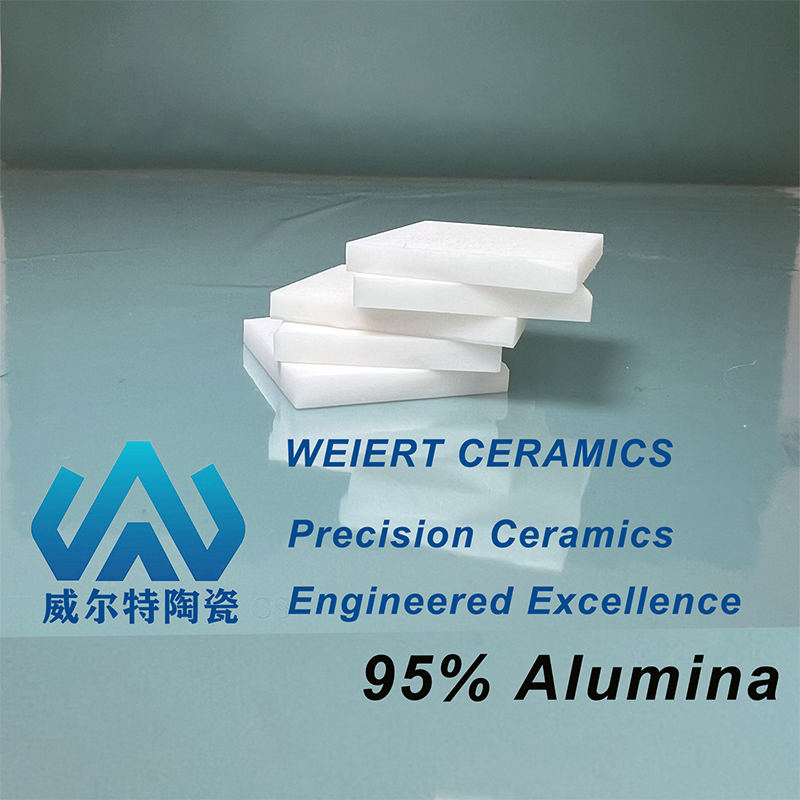

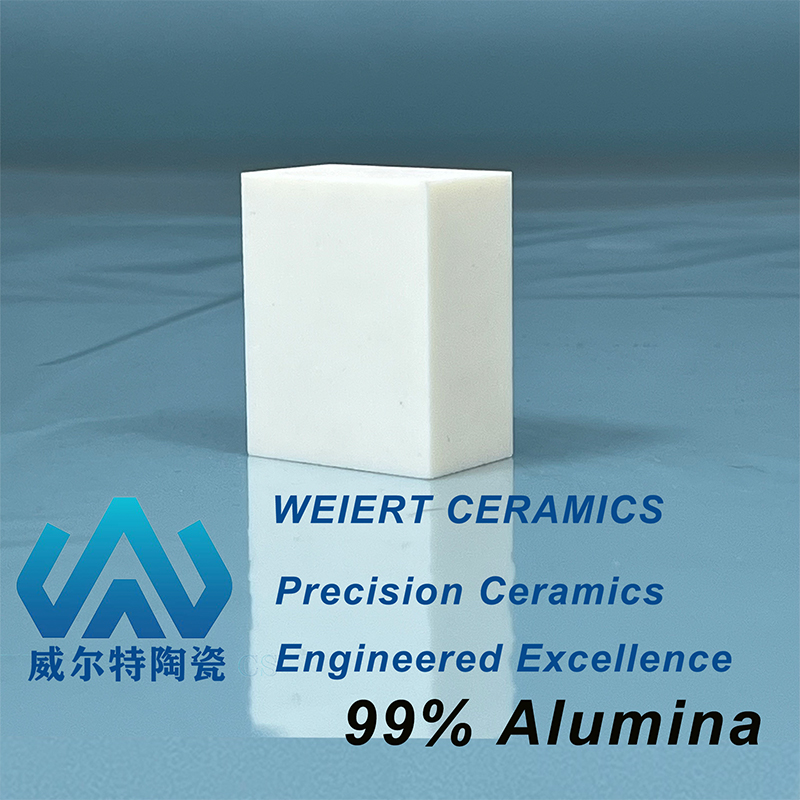

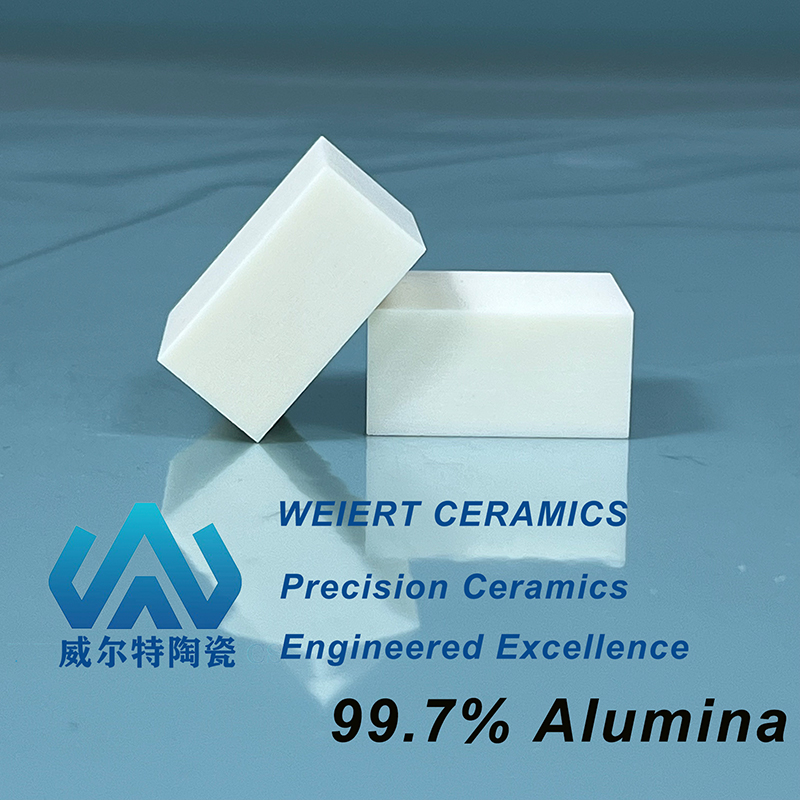

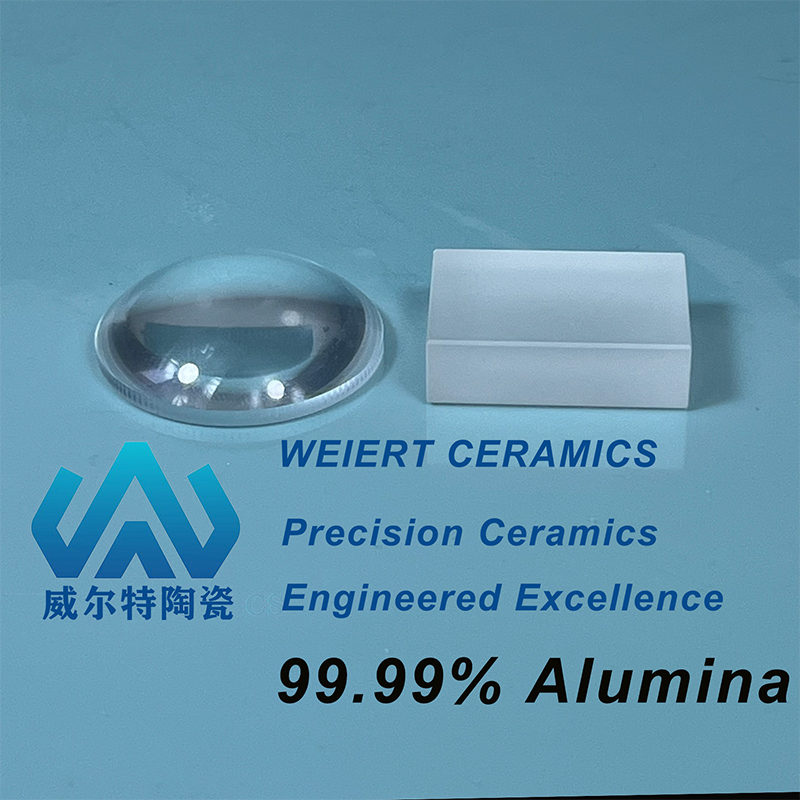

The most commonly used alumina ceramics contain 90% or more Al₂O₃, with varieties such as 95%, 99%, 99.7%, and 99.99% purity. Alumina with 99.99% purity is often semi-transparent or transparent, known as sapphire.

Key Properties of Alumina Ceramics Advantages:

High Melting Point

High Hardness

Chemical Corrosion Resistance

Outstanding Dielectric Properties

Superior Optical Properties (for 99.99% Transparent Alumina)

Disadvantages:

Low toughness, relatively brittle.

General

| property | Unit | 95%Al2O3 | 99%Al2O3 | 99.7%Al2O3 | 99.99%Al2O3 |

| Colour | white | Ivory | Ivory | Icy/Off White | |

| Density | g/cm³ | 3.72 | 3.9 | 3.92 | 3.98 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Gas Permeability | atms-cc/sec | gas tight <10⁻¹º | gas tight <10⁻¹º | gas tight <10⁻¹º | gas tight <10⁻¹º |

| Optical Transmission | μm | 0.3 ~ 5 | |||

| Reflection Loss | dB | 0.2 |

Mechanical Properties

| Propertiy | Unit | 95%Al2O3 | 99%Al2O3 | 99.7%Al2O3 | 99.99%Al2O3 |

| Vickers Hardness (500 gm) | GPa (kg/mm2 ) | 11.5 (1175) | 12.7 (1300) | 15(1530) | 19.6(2000) |

| Rockwell Hardness | R45N | 79 | 81 | 86 | 91 |

| Compressive Strength @ 25°C | MPa (psi x 10³) | 1827 (265) | 2241 (325) | 2240 (325) | 2413 (350) |

| Flexural Strength (MOR) (3 point) @ 25°C |

MPa (psi x 10³) | 310 (45) | 393 (57) | 379 (55) | 455 (66) |

| Fracture Toughness (Notched Beam) | MPam1/2 | 3-4 | 4-5 | 3-4 | 5-6 |

| Modulus of Elasticity | GPa (psi x 10⁶) | 303 (44) | 345 (50) | 379 (55) | 393 (57) |

| Poissons Ratio | 0.22 | 0.23 | 0.23 | 0.23 | |

| Tensile Modulus @ 25°C | MPa (psi x 10³) | 151 (22) | 221 (32) | 200 (29) | 275 (40) |

Thermal Properties

| Property | Unit | 95%Al2O3 | 99%Al2O3 | 99.7%Al2O3 | 99.99%Al2O3 |

| Thermal Conductivity @ 25°C | W/m-K | 20 | 30 | 30 | 35 |

| Specific Heat Capacity | J/g-°C | 0.88 | 0.88 | 0.90 | |

| C.T.E. 25 – 100°C | x 10⁻⁶/C | 6.1 | 6.2 | 6.5 | 6.5 |

| C.T.E. 25°-300°C | x 10⁻⁶/C | 7.0 | 6.8 | 7.8 | 7.8 |

| C.T.E. 25°-600°C | x 10⁻⁶/C | 7.7 | 7.6 | 8.0 | 8.1 |

| Max.Service Temp.Air/Inert | Fahrenheit (°F) | 3000 | 3000 | 3000 | 3000 |

| Celsius (°C) | 1650 | 1650 | 1650 | 1650 |

Electrical Properties

| Property | Unit | 95%Al2O3 | 99%Al2O3 | 99.7%Al2O3 | 99.99%Al2O3 |

| Dielectric Constant @ 1 MHz | 9.2 | 9.5 | 10 | ||

| Dielectric Constant @ Gigahertz | 11 | 9.8 | 9.6 | ||

| Dielectric Loss @ 1 MHz | 0.0009 | 0.0005 | < .0001 | ||

| Dielectric Loss @ Gigahertz | 12.5 | 9.8 | 9.6 | ||

| Dielectric Strength (.125” Thick) | V/mil | 250 | 260 | 290 | 430 |

| Volume Resistivity @ 25°C | ohms-cm | > 1 x 10¹⁴ | > 1 x 10¹⁴ | > 1 x 10¹⁴ | > 1 x 10¹⁴ |

| Volume Resistivity @ 300°C | ohms-cm | 5 x 10¹² | 8 x 10¹¹ | 3 x 10¹² | 1 x 10¹³ |

| Volume Resistivity @ 500°C | ohms-cm | 3 x 10⁹ | 2 x 10⁹ | 6 x 10¹º | 5 x 10¹² |

| Volume Resistivity @ 700°C | ohms-cm | 3 x 10⁸ | 2 x 10⁸ | 6 x 10⁹ | 1 x 10¹² |

*The values represent typical material properties and may vary depending on product configuration and the manufacturing process. For further information, do not hesitate to contact us.

Applications of Alumina Ceramics

Alumina ceramics are widely used across a range of industrial and biomedical fields, including but not limited to:

- Vacuum Electronic Devices

- Thick and Thin Film Circuit Substrates

- Spark Plug Insulators

- Textile Ceramic Components

- Abrasives, Grinding Tools, and Ceramic Cutting Tools

- High-Temperature Structural Parts

- Sapphire (99.99% Al₂O₃) can be used for periscopes, scopes, and measurement instrument lenses.

Alumina Ceramic Material Grades-4 Purity Levels

95% Alumina (A12O3)

99% Alumina (A12O3)

99.7% Alumina (A12O3)

99.99% Alumina ( A12O3)

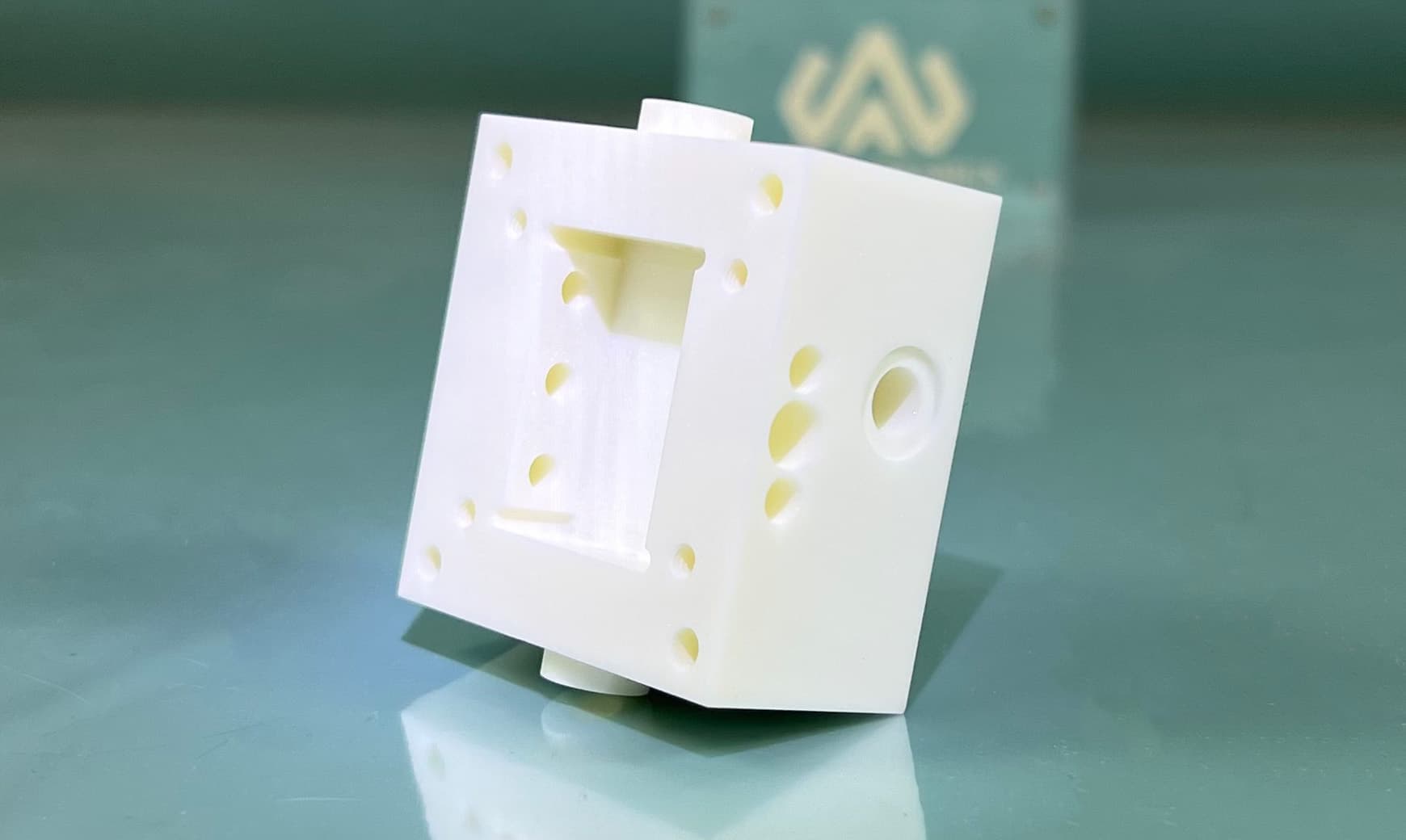

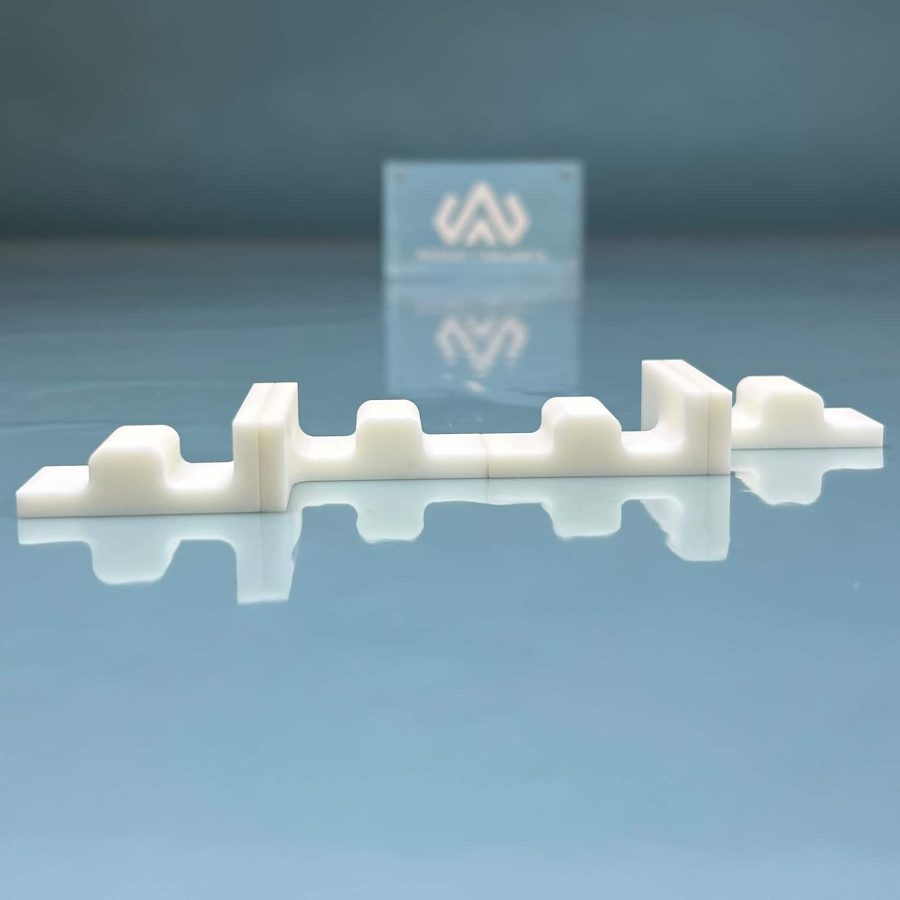

CNC-machining Alumina ceramics

Yixing WEIERT Ceramics Technology Co., Ltd. is a leading manufacturer and exporter of alumina ceramics. With a dedicated research and development (R&D) department for ceramic materials, we continuously innovate and enhance material performance to meet the diverse needs of our customers. Unlike trading intermediaries, we are a direct manufacturer with full in-house capabilities, allowing us to control the entire technical ceramic production process—from raw material production and sintering to CNC machining. Since 2016, we have produced over 5,000 types of precision ceramic products for hundreds of companies.

Custom Alumina Oxide Ceramic Component Services:

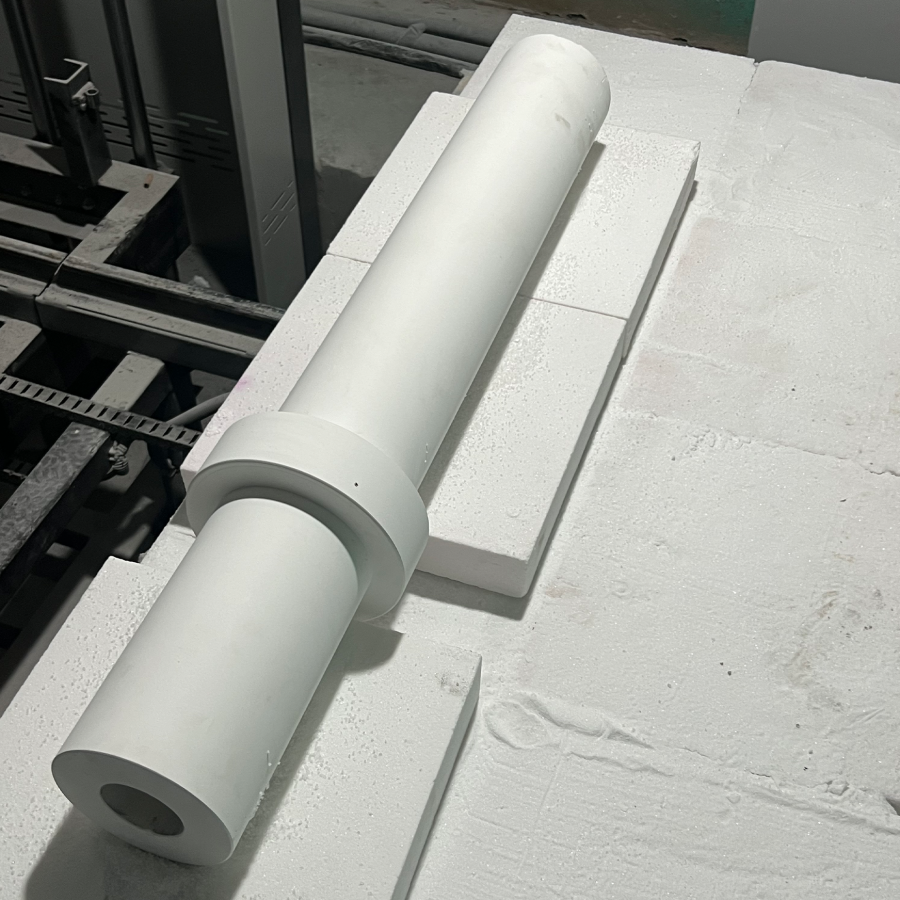

Alumina ceramic tubes

CNC-machining Alumina ceramics

Precision Alumina ceramics

Custom Alumina ceramic parts

Large Alumina plates (High Purity Alumina)

Large Alumina Components

CONTACAT US