Overview of Advanced Ceramic Materials (2025)

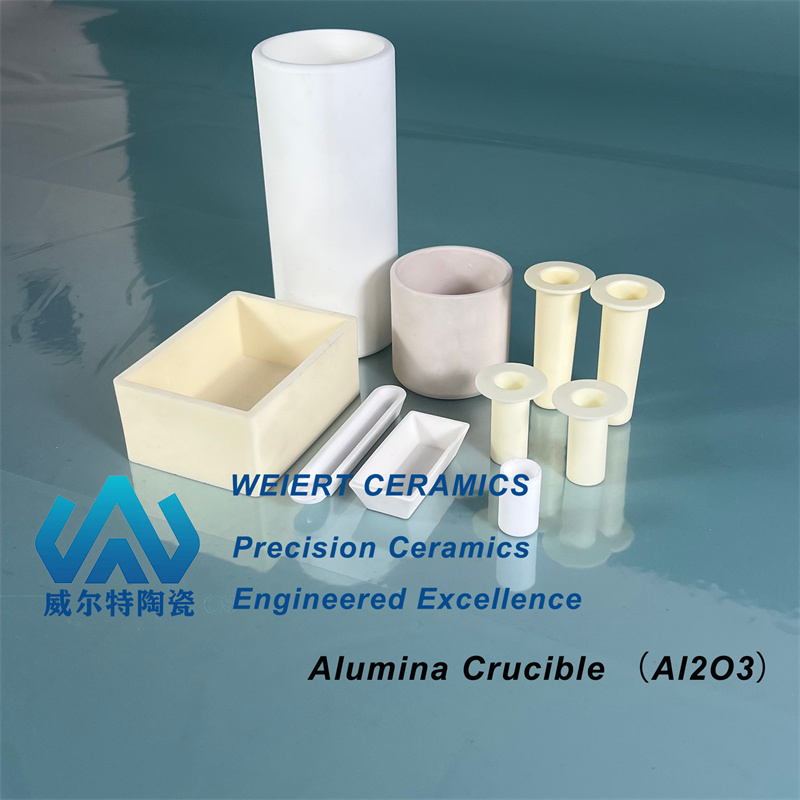

Advanced ceramics, also known as Fine Ceramics, Technical Ceramics, or Precision Ceramics, are a specialized class of industrial ceramics.

These materials are composed of high-purity, inorganic, non-metallic compounds, either naturally occurring or synthetically produced. They are processed into polycrystalline solids through precise shaping and high-temperature sintering techniques.

To achieve specific properties or unique functionalities, advanced ceramics require carefully controlled chemical compositions, strict forming processes, and elevated sintering temperatures to fine-tune their microstructures.

Thanks to their exceptional properties, advanced ceramics are widely used in aerospace equipment, laser systems, electronic devices, military applications, traditional energy systems, renewable energy technologies, fluid control systems, and semiconductor manufacturing equipment.

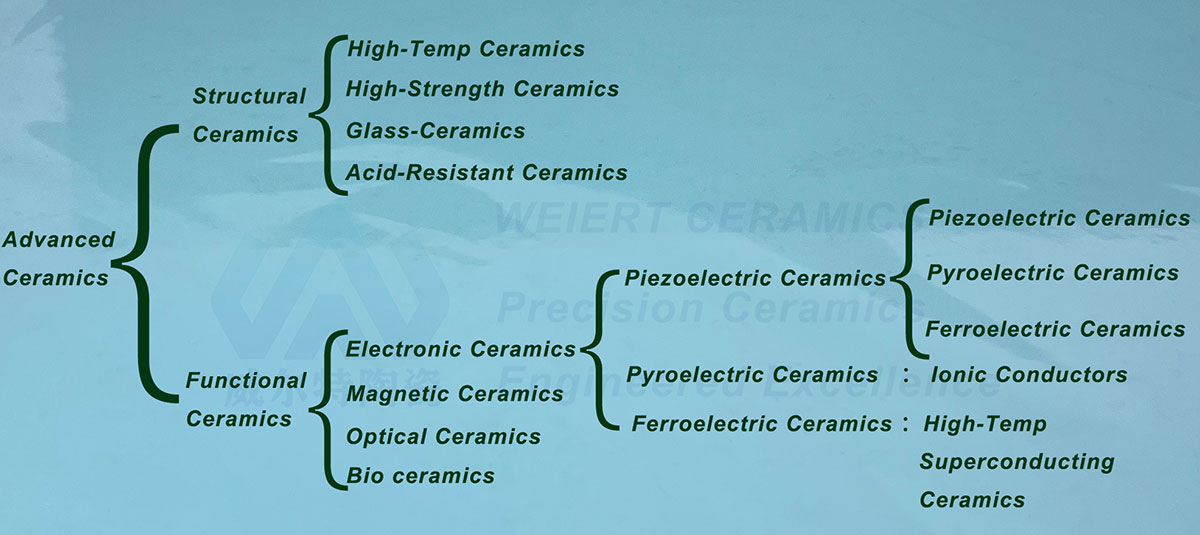

Comprehensive Guide to Advanced Ceramics: Structural and Functional Ceramics Categories and Applications

Advanced Ceramics Categories: Chemical Composition Classification (Oxides, Nitrides, Carbides, Borides)

| Category of Advanced Ceramics | Major Advanced Ceramic Materials |

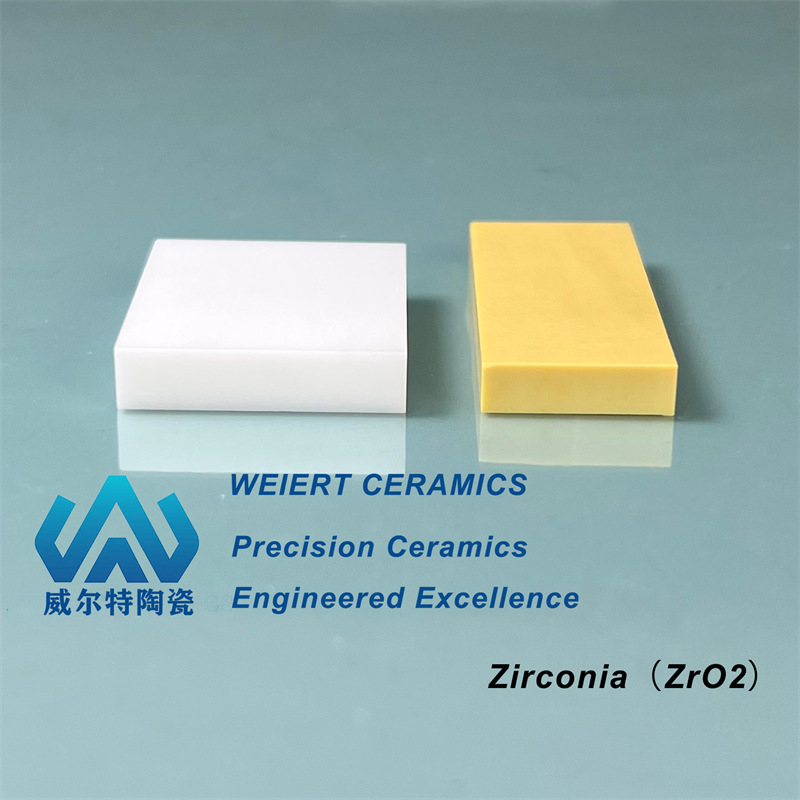

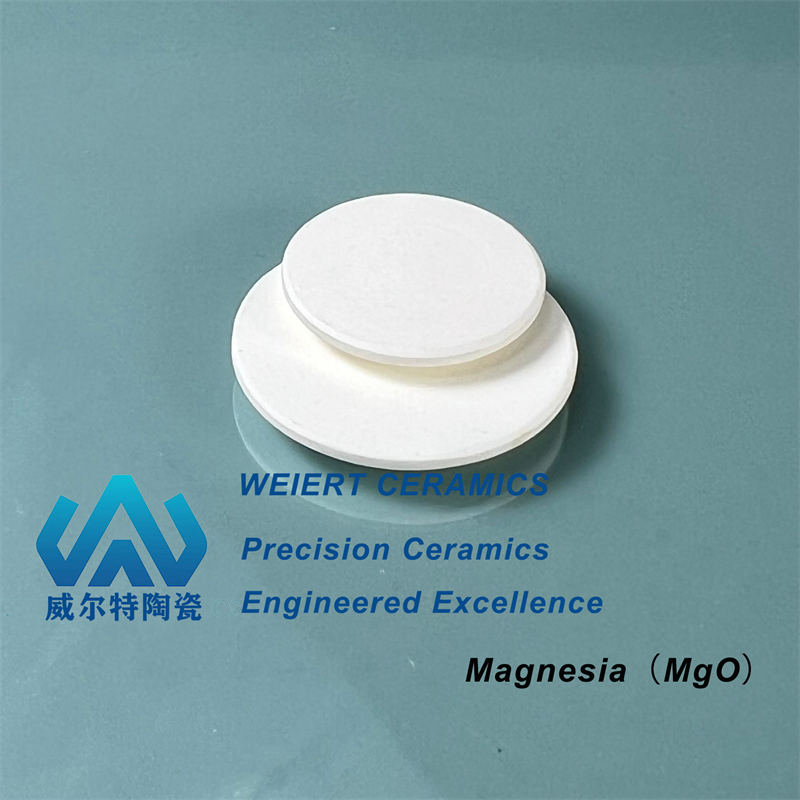

| Oxides | Al₂O₃, SiO₂, MgO, BeO, ZrO₂, TiO₂, V₂O₅, MgAl₂O₄, 3Al₂O₃·2SiO₂, BaTiO₃, CaTiO₃, PZT, PbTiO₃ |

| Carbides | SiC, TiC, WC, B₄C |

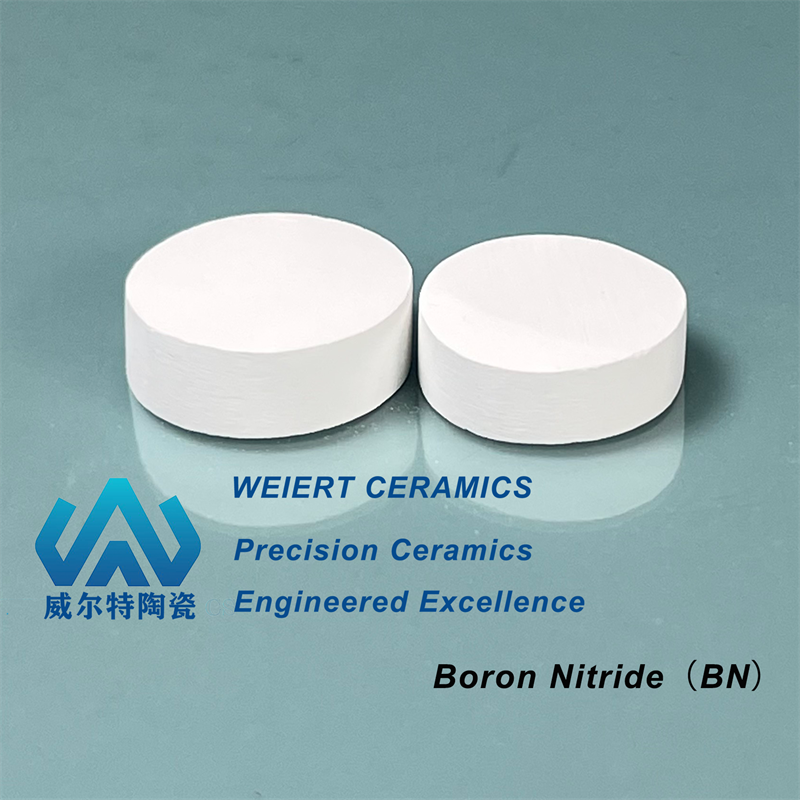

| Nitrides | Si₃N₄, TiN, BN, AlN, C₃N₄ |

| Borides | TiB₂, ZrB₂ |

Trusted Advanced Ceramics Manufacturer

WEIERT CERAMICS is a manufacturer specializing in innovation and production of advanced ceramics, not a trading company. Guided by the philosophy of Kazuo Inamori, we integrate his principles into our business management and manufacturing practices. We are committed to optimizing management processes and driving technological innovation to provide advanced ceramic products that meet customer expectations in quality while remaining competitively priced.

Ceramic Strength & Durability

Focusing on compressive strength, toughness, and wear resistance to ensure reliable performance.

Ceramic Thermal Performance

Emphasizing thermal conductivity, expansion, and stability to optimize heat management.

Ceramic Electrical Properties

Considering insulation, conductivity, and dielectric strength for efficient functionality.

Ceramic Chemical Resistance

Focusing on corrosion resistance and stability to protect against chemical degradation.