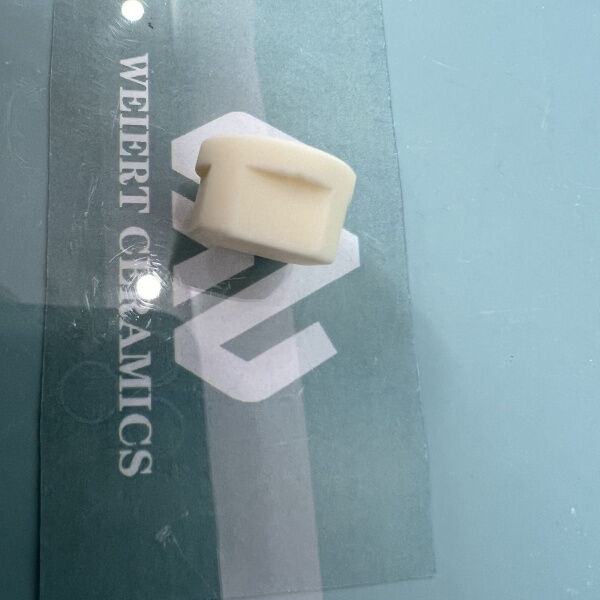

Ceramic nuts would feel the latest innovation in the market, supplying a safer and most efficient option traditional steel nuts. Weiert Ceramics nuts are constructed with ceramic materials known due to their durability, security, and high efficiency. They've been popular in various businesses like automotive, aerospace, construction, and more. This article explores the advantages being different uses, quality, and safety of ceramic nuts.

Ceramic nuts are this Weiert Ceramics product can be superior markets simply because they have an advantages than traditional other nuts. Firstly, ceramic nuts offer better safety due to their high-performance items, which are more durable and heat resistant. Secondly, ceramic material nuts are less prone to corrosion, it increases their lifespan and reduces repair costs. Moreover, ceramic nuts are much lighter and smaller in size, permitting better efficiency and improved performance in a variety of applications.

Ceramic nuts are considered innovative due to the components used to produce them. Ceramic nuts are constructed of high-quality, high-performance ceramics that cause them to durable and resistant to damage and use. In addition, Weiert Ceramics nut feature superior thermal surprise resistance, which makes alumina ceramic material ideal to become used in high-temperature applications.

Ceramic nuts are created to be safer than conventional metal nuts. Weiert Ceramics are made of maybe materials maybe not prone to heat or corrosion damage, making them more unlikely to fail. Ceramic nuts are fully non-flammable and non-conductive, makes them ideal for use in potentially environments being dangerous construction. Moreover, ceramic machine parts and nuts are not magnetic, means they is safe for use in electrical applications where interference are magnetic concern.

Ceramic nuts may be put in various applications since they are lightweight, small in measurements, and efficient. Weiert Ceramics nut may become used in the automotive, aerospace, construction, and companies electrical. They are suitable for use in bolts, nuts, and washers, among other applications. The precision ceramic parts of nuts can be used in high-temperature applications like engines, turbines, and heaters.

Speedy Delivery Weiert a leading producer with modern production equipment well as ceramic nutscapacity to ensure timely delivery orders from customers. have optimized production processes to shorten delivery cycles improve production efficiency. are able to deliver large orders within stipulated dates, even if they are high-volume. have also developed long-term relationships with reliable logistic suppliers ensure that the products are delivered safely and swiftly our clients.

Continuously delivered With more than decade of expertise in advanced ceramics, Weiert has accumulated vast amount of ceramic nuts. We adhere to rigorous requirements strict standards to ensure that products are of the highest quality. company is well-established and we've got a production system which allows us to manage every step, from raw materials to the final product ensure that it is with same quality.

Flexible Options Weiert offers personalized customizing services for customers. We understand that each customer's requirements individual to each client. By establishing a clear communication with customers and their requirements, are able to design products that are able ceramic nutstheir specific application requirements. are able to adapt to any specific requirements of customer whether it's product dimensions shapes, or even performance parameters.

Strict Inspection Weiert established a ceramic nutsquality management system has been awarded ISO International Quality Certification. strictly follow the industry's standards regulations closely monitor every aspect of production. Each process, from raw material selection through product inspection inspection at the end, is subjected to rigorous quality control order to ensure the highest quality product performance. quality assurance team who conducts regular testing and sampling to identify potential problems ensure our customers have peace mind.

Ceramic nuts can similarly be utilized to metal which was traditional. However, it is critical to ensure proper installation. For installation, Weiert Ceramics should be used along with ceramic washers to avoid breaking and damage. Ceramic alumina custom parts should be tightened to the suitable torque per the maker's instructions. Regular repair and inspections should be conducted to ensure functionality that was proper.

Ceramic nuts are linked to the highest quality as a total result of the materials accustomed create them. Weiert Ceramics materials used in the creation of customized ceramic parts are known to be durable, corrosion-resistant, and resistant to wear and tear. Moreover, ceramic nuts undergo rigorous testing and inspection to make sure that they satisfy business criteria.