Magnesia Crucible MgO

Magnesium Oxide Crucible

In the field of high-temperature metallurgy and induction melting, the purity and stability of the crucible directly influence the cleanliness and performance of the end material. For companies producing nickel-based superalloys, precious metals, and advanced ceramics, a High-Purity Magnesium Oxide (MgO) Crucible is increasingly becoming the core refractory container.

Magnesium oxide (MgO) offers exceptional properties:

- A melting point of up to 2,852 °C;

- High resistance to metal oxides and alkaline slags;

- Superior chemical stability compared to Al₂O₃;

- Good electrical insulation and relatively low thermal expansion.

These characteristics make MgO the preferred crucible material for induction furnaces , induction melting furnaces, and electron-beam melting equipment.

WEIERT Ceramics’ Manufacturing Approach

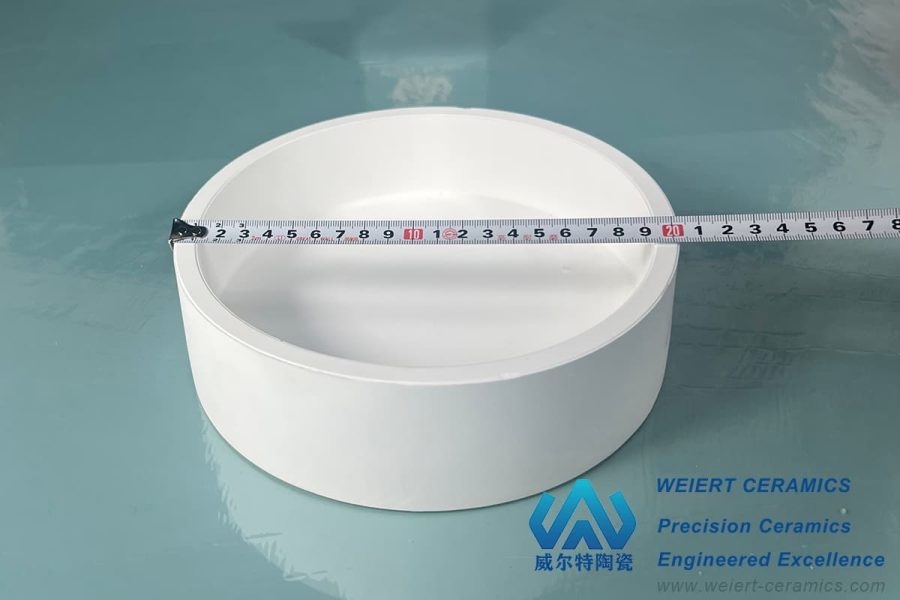

Based on studies of high-purity MgO ceramics (e.g., industry data showing >99 % MgO content and high bulk density), Weiert Ceramics applies advanced forming and refining techniques to ensure excellent structural stability and consistency.

- Our process combines Cold Isostatic Pressing (CIP) for uniform particle distribution and high densification, together with electrofused re-crystallisation to achieve oriented grains and ultra-low impurities.

- Sintering parameters are precisely controlled, and with ultra-pure MgO feedstock the resulting crucibles reach purity levels above 99.5 % and bulk density around 3.4 g/cm³, providing outstanding thermal and chemical stability.

Anti-hydration and long-term stability

Because MgO is prone to hydration, we adopt the following improvements:

- Micro-additions of Al₂O₃, CaO and Ga₂O₃ to improve densification and reduce residual porosity;

- Surface sol–gel pore-sealing coatings;

- Vacuum-sealed, moisture-controlled packaging during storage and transport.

Performance & applications

High-purity MgO crucibles are used in:

- Induction melting of nickel-based superalloys;

- Refining of platinum, iridium, palladium and other precious metals;

- Melting of lithium-ion cathode precursor materials, rare-earth oxides, and high-purity metal melts.

Independent factory data show that in a 1,700 °C vacuum environment, Weiert Ceramics’ crucibles achieve continuous operation of over 20 hours without structural failure.

Summary

High-purity MgO crucibles represent the high-end direction of refractory ceramic materials. Weiert Ceramics, leveraging ultra-pure raw materials and custom sintering processes, offers customers crucible solutions with higher purity and longer service life.

References:

- Jin Yan, Development of Magnesia Crucible Products, Ceramics, 2006.

- Chen Guangyao et al., Interface Reaction Mechanism between MgO Crucible and Ni-Based Superalloy, Journal of the Chinese Ceramic Society, 2024.

- Wu Chaowan, Studies on MgO Crucible in Vacuum Induction Furnace for Pure Iron Melting, Acta Metallurgica Sinica, 1964.