Ultra-fine powder classification technology precisely separates micron-sized particles by size using specialized equipment. It is widely applied to non-metallic ultra-fine powders and other materials in industries such as electronics, advanced ceramics, and high-temperature coatings.

The air classifier is a essential part for processing ultra-fine powders. Its main components include the inlet, air intake, outlet, cone body, classification chamber, and motor. The working principle relies on the adjustable rotational speed of the classifier wheel, which generates centrifugal force and interacts with the airflow entering through the air intake. These forces influence the movement of particles of different sizes within the classification chamber, achieving highly accurate particle size separation.

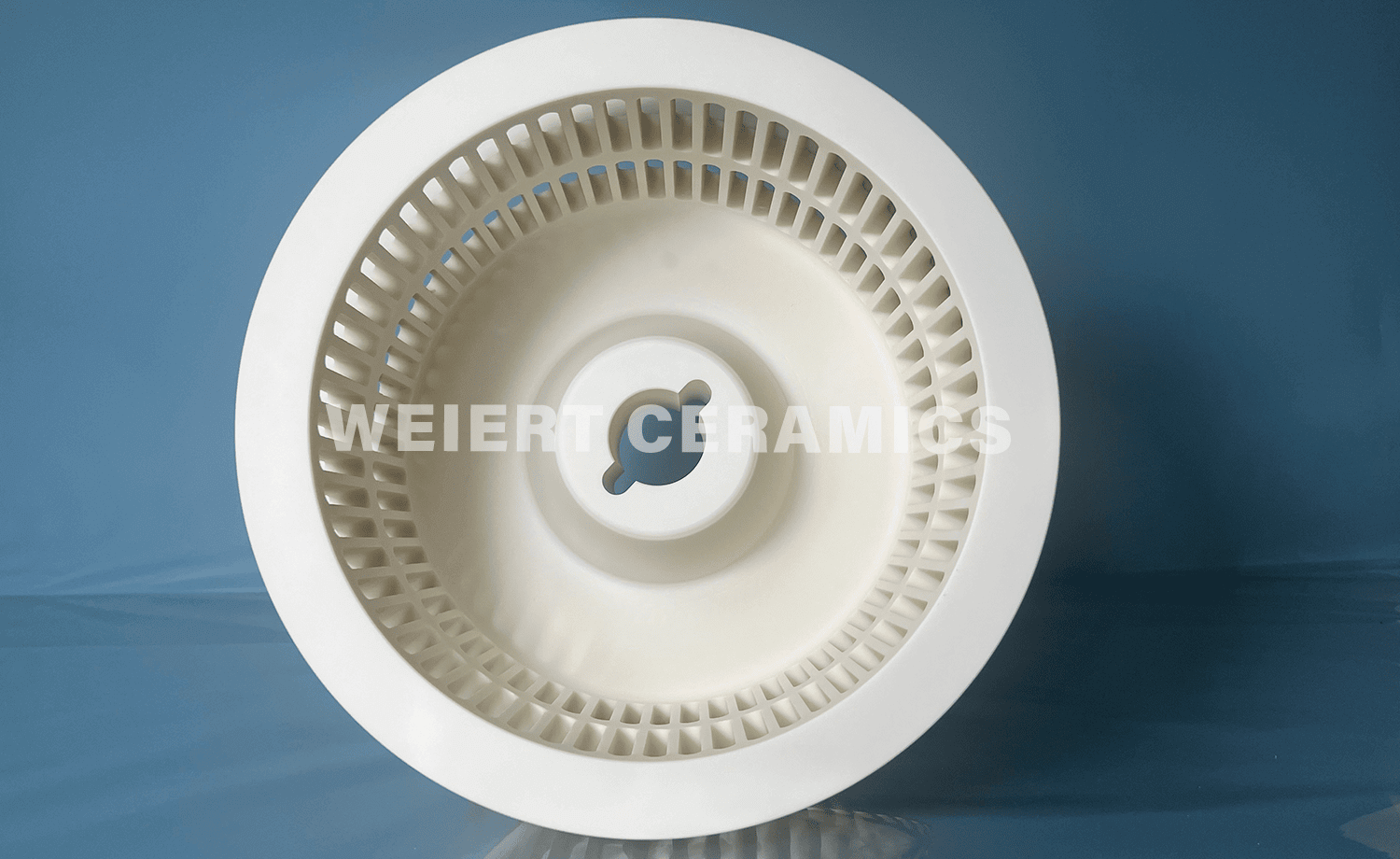

The classifier wheels are the essential components for air classifiers and are generally made from metallic or non-metallic materials. For applications where magnetic contamination must be avoided, non-metallic classifier wheels are typically used, and they are made from advanced ceramics such as zirconia, alumina, or silicon carbide.

Manufacturing an integrated ceramic classifier wheel presents two main challenges: sintering and CNC machining. Finally, We must ensure that the wheel passes dynamic balance tests even at speeds of up to 6,000 RPM, so that it can maintain stable and efficient operation during actual use.

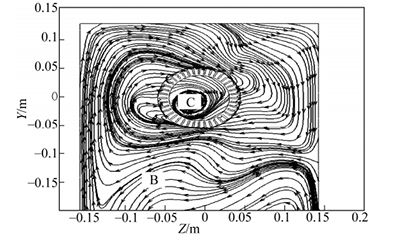

The Streamline Distribution Inside The Classification Chamber

The image further illustrates the distribution of gas streamlines in the longitudinal section of the classification chamber. As shown in the figure, the airflow forms irregular horizontal vortices around the classifier wheel. It is noteworthy that the airflow in the outer region of this type of classifier wheel flows in the same direction as the wheel's rotation, and the flow patterns inside and outside the classifier wheel are consistent.

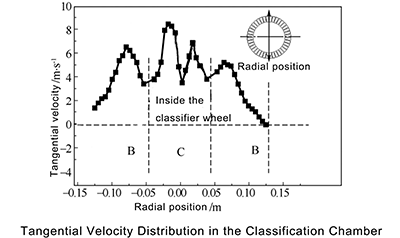

In ultrafine powder centrifugal classification, the magnitude of the tangential velocity directly affects the centrifugal force experienced by the particles. The tangential velocity distribution within the classification chamber is shown in the figure. For this type of classifier, the tangential velocity in the classification chamber is entirely positive. As the airflow enters the gaps between the rotor blades, the tangential velocity remains stable. This prevents discrepancies in tangential velocity between the inner and outer regions of the classifier wheel, thereby avoiding uneven force field distribution at the outer edge of the wheel, which would otherwise reduce particle classification efficiency.

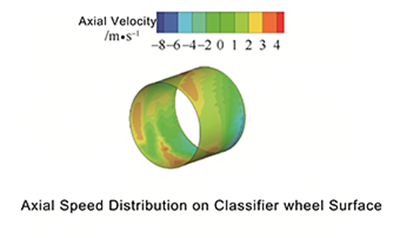

The image displays a contour plot of the axial velocity distribution on the cylindrical surface of a classifier wheel with an outer diameter of 100 mm. The axial velocity distribution on the outer surface of the classifier wheel for this classifier is relatively uniform, with velocity values close to zero in most areas. Any presence of axial velocity would lead to airflow velocity fluctuations, which are detrimental to maintaining a stable flow field and would negatively impact classification accuracy.

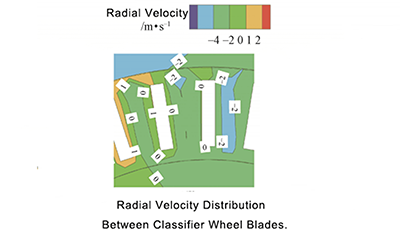

The image shows a contour plot of the radial velocity distribution of airflow between the blades of the classifier wheel, where the symbol "-" indicates gas flowing toward the center of the rotor. From the image, it can be observed that the radial velocity between the blades of this classifier wheel varies within the range of –2~1m/s, with the velocity distribution being relatively uniform.

WEIERT CERAMICS TECHNOLOGY is a direct manufacturer of technical ceramics in China—not a trading intermediary. We supply high-performance ceramic components to powder processing equipment manufacturers and provide direct solutions to end-users of these systems.

With nearly 10 years of experience in technical ceramics production, we are confident in our ability to deliver high-quality, customized ceramic classification wheels and other technical ceramic products. If you're looking for a reliable partner for ceramic solutions, contact us now! I’m confident that our competitive pricing will leave you with a big smile!

References:

[1] SHAPIRO M,GALPERIN V.Air classification of solid particles: a review[J].Chemical Engineering and Processing,2005,44(2):279-285.

[2] XU N,LI G,HUANG Z.Numerical simulation of particle motion in turbo classifier[J].China Particuology,2005,3(5):275-278.

[3] 2016,22(2):82-85.DANG D,WANG K J.Effect of classifier wheel speed on particle size distribution[J].China Powder Science and Technology,2016,22(2):82-85.

[4] 2015,66(s1):159-164. DANG D,WANG K J.Effect of feeding rate on flow field inside classifier[J].Journal of Chemical Industry and Engineering(China), 2015,66(s1):159-164.

[5] TONEVA P,EPPLE P,BREUER M,et al.Grinding in an air classifier mill — Part I : Characterisation of the one-phase flow[J].Powder Technology,2011,211(1):19-27.

[6] TONEVA P,WIRTH K E,PEUKERT W.Grinding in an air classifier mill—Part II:Characterisation of the two-phase flow[J].Powder Technology,2011,211(1):28-37.

[7] JIANG S Z,GE X L,WANG J X.Study of flow field in a horizontal turbo classifier[J].Non-Metallic Mines,1999,22(3):35-37.

[8] WANG X,GE X,ZHAO X,et al.Study on horizontal turbine classification[J].Powder Technology,1999,102(2):166-170.

[9] LIU D,SONG Y.Experimental study of guide disc structure of FJJ model vortex classifier[J].Sulphur Phosphorus & Bulk Materials Handling Related Engineering,2012,111(6):13-15.

[10] SUN Z P,SUN G G,XU J.Effect of deflector on classification performance of horizontal turbo classifier[J].China Powder Science And Technology,2016,22(1):6-10.

[11] BAUDER A,MÜLLER F,POLKE R.Investigations concerning the separation mechanism in deflector wheel classifiers[J].International Journal of Mineral Processing,2004,74:S147-S154.

[12] REN W J,LIU J X,YU Y.Design of a rotor cage with non-radial arc blades for turbo air classifiers[J].Powder Technology,2016,292:46-53.

[13] YUE D X,DIAO X,LI S Y,et al.Computation of classifier cut size based on analysis of particle tracks[J].Chemical Industry and Engineering Progress,2012,31(9):1919-1925.

[14] TONG C,LI S Y,LI X.Numerical simulation on particles classification trajectory using unsteady tracking[J].Chemical Industry and Engineering Progress,2013,32(9):2061-2067.