Składniki magnezji, MgO

Pierścień magnezjowy (MgO)

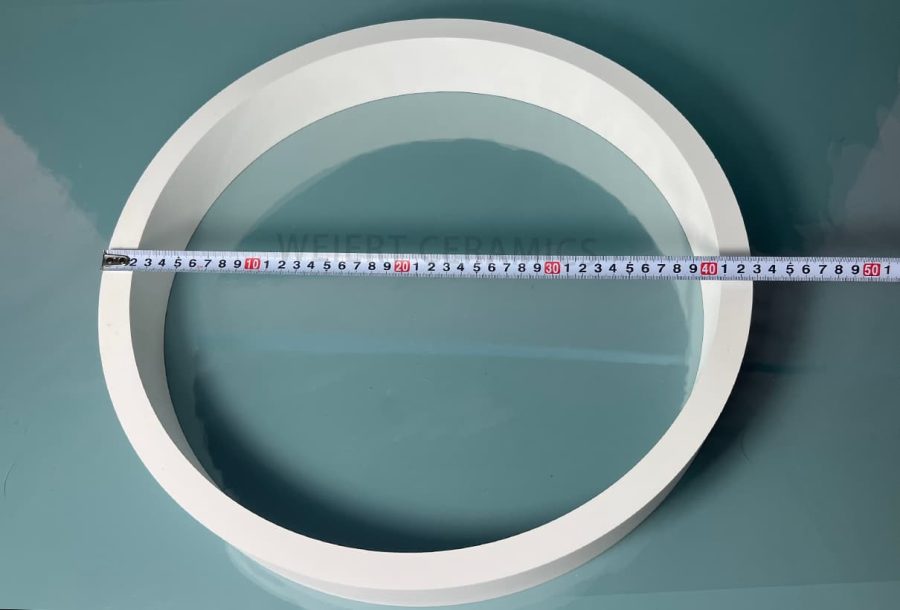

Magnesia Support Ring for High-Temperature Firing

This magnesia support component is used for high-temperature firing in furnaces. It serves as a stable base to support ceramic or refractory products during sintering or heat treatment. It offers good thermal stability and electrical insulation

The following are the detailed product specifications.

| Parameter | Description |

| Czystość | 99.70% |

| Diameter(OD x ID x H) | 430 x 44 x 60 mm |

| Max Temp | 2200℃ |

| Custom Size Available | yes |

| Max Size Available | 500x 380 x 400 mm |

| Customizable Composition | yes |

| Electrical Insulation | yes |

| Temperature Ramp Curve | 180°C/h |

Magnesia Ceramic China Supplier

The production of magnesia (MgO) ceramics mainly involves several forming methods, including slip casting, hot injection molding, cold isostatic pressing (CIP), and dry pressing. These are followed by sintering and CNC machining to achieve the desired final shape and precision.

At present, customized magnesia ceramic components are in high demand. Our diverse manufacturing capabilities enable us to meet a wide range of custom requirements with high precision and efficiency.

MgO Ceramic China Factory

We specialize in CNC machining of MgO ceramics, offering tailored solutions for various industrial applications.