- PRODUCT DETAILS

- RELATED PRODUCTS

- Inquiry

PRODUCT DETAILS

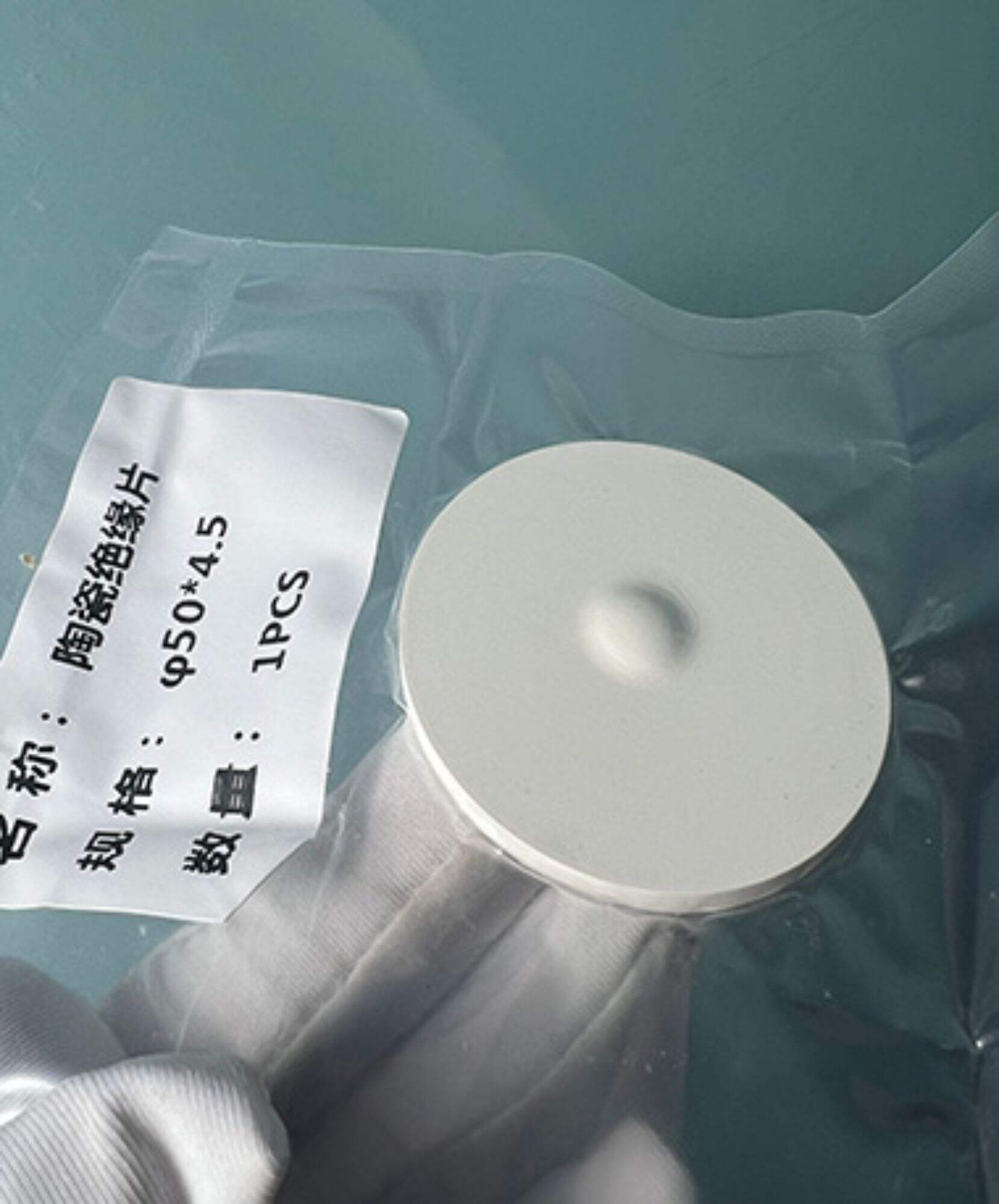

Zirconia is an exceptional high-temperature ceramic material; however, pure zirconia undergoes phase transformation at elevated temperatures, resulting in volume expansion and strength deterioration. To address this issue, a certain amount of magnesium oxide (MgO) is typically incorporated into zirconia to form a magnesia-zirconia composite material. Magnesium oxide effectively stabilizes the cubic phase structure of zirconia, thereby suppressing phase transformation at high temperatures and preventing volume expansion. Additionally, by refining the grains and achieving a uniform microstructure, it enhances the material's strength and toughness. Magnesia-zirconia composites exhibit superior thermal shock stability and can withstand more severe temperature fluctuations without fracturing due to the stabilizing effect of magnesium oxide on the phase structure of zirconia as well as excellent thermal expansion matching between the two components. The addition of magnesium oxide promotes sintering of zirconia, lowers sintering temperature requirements, and enables dense sintered bodies to be obtained. This characteristic is advantageous for producing high-performance magnesia-zirconia ceramic products with broad application prospects in fields such as high-temperature structural components, refractory materials, electronic ceramics, aerospace industry applications, semiconductor manufacturing processes.

RELATED PRODUCTS

Inquiry

Contact Us

Minimum order quantity of 50

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA