- PRODUCT DETAILS

- RELATED PRODUCTS

- Inquiry

PRODUCT DETAILS

Magnesia-zirconia plates find extensive applications in various high-temperature equipment. Here are some specific examples:

Glass melting furnaces:

Names: Glass melting furnace sidewall magnesia-zirconia lining plates, glass melting furnace roof plates

Function: Protect the furnace lining and extend its service life

Steel ladles:

Names: Steel ladle magnesia-zirconia sliding plates, steel ladle magnesia-zirconia seat bricks, steel ladle magnesia-zirconia lining plates

Function: Protect the steel ladle lining and enhance its refractory performance

Petroleum cracking units:

Names: Regenerator magnesia-zirconia baffle plates, cyclone separator magnesia-zirconia lining plates

Function: Resist high temperatures and corrosion, prolonging equipment service life

Incinerators:

Names: Incinerator magnesia-zirconia lining plates, incinerator flue magnesia-zirconia lining plates

Function: Withstand high temperatures and corrosion, protecting the equipment

Aerospace engines:

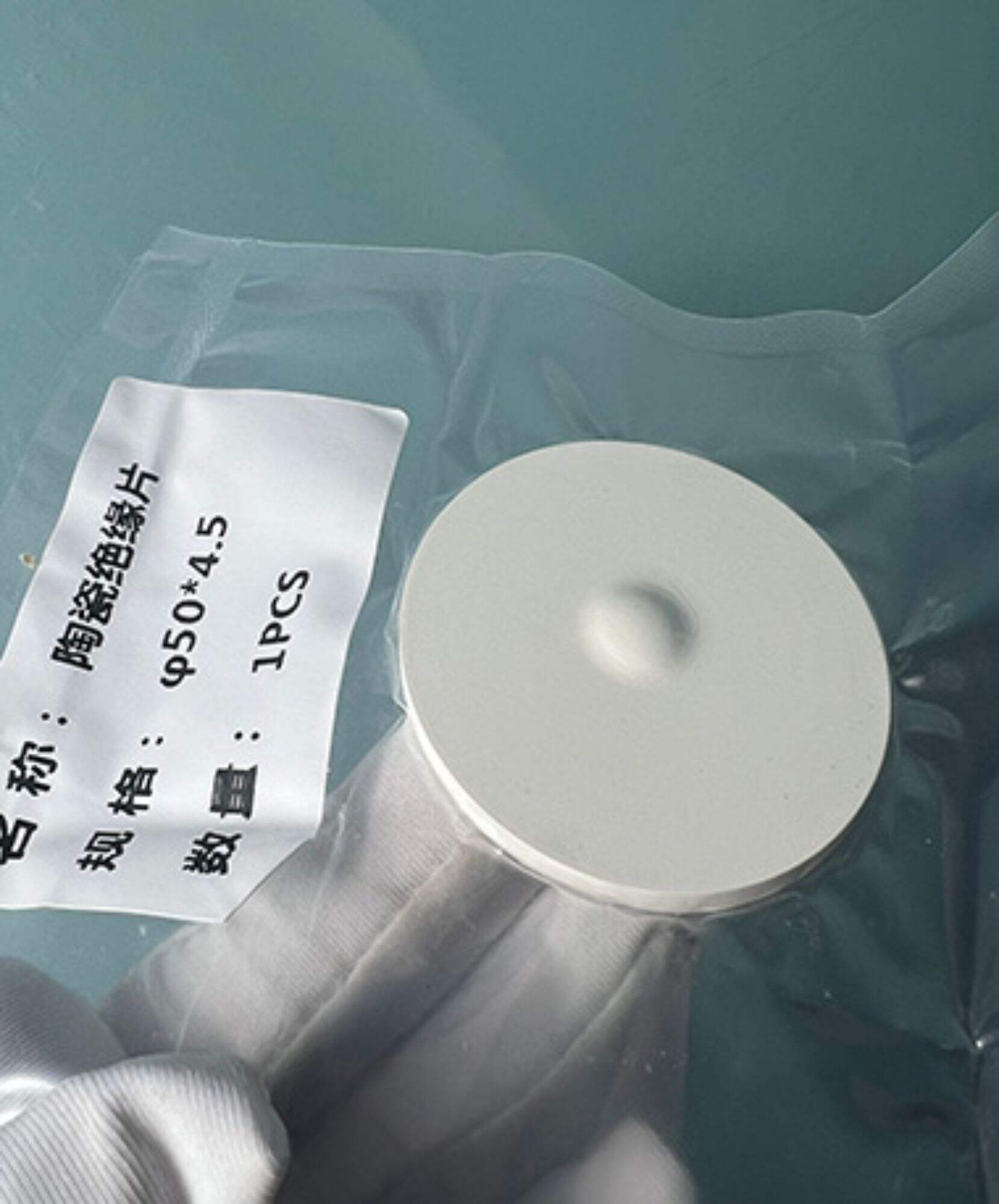

Names: Nozzle magnesia-zirconia insulation plates, combustion chamber magnesia-zirconia insulation plates

Function: Protect engine components and enhance high-temperature resistance

Semiconductor manufacturing equipment:

Names: High-temperature diffusion furnace magnesia-zirconia lining plates, epitaxial furnace magnesia-zirconia lining plates

Function: Provide a clean, high-purity, high-temperature environment

Heat treatment equipment:

Names: Quenching furnace magnesia-zirconia lining plates, tempering furnace magnesia-zirconia lining plates

Function: Protect furnace components and improve refractory performance

RELATED PRODUCTS

Inquiry

Contact Us

Minimum order quantity of 50

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA