Custom CNC Machining of Zirconia Ceramics

As an advanced technical ceramics manufacturer in China, WEIERT Ceramics specializes in precision ceramic machining

and the production of custom ceramic components. In particular, we offer high-precision zirconia ceramic tubes, rods, and

various zirconia structural parts. Simply provide us with your drawings, and we will promptly offer you a quotation.

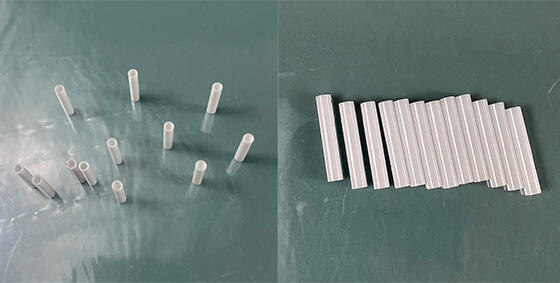

These zirconia tubes will be rotating extremely fast in a precise chamber using pneumatic bearing.

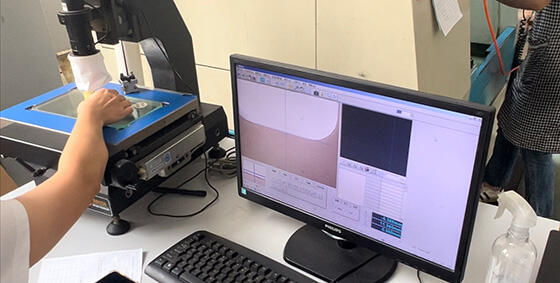

So the outer diameter and concentricity are critical.

Our custom zirconia tubes are designed for high-speed rotation in precision chambers using pneumatic bearings.

To ensure optimal performance, the outer diameter and concentricity of these tubes are crucial,

meeting strict tolerances for accurate functionality.

| Item Name | ZrO2 Tube |

| Length | 18 mm |

| Outer Diameter | 3.2 mm |

| Inner Diameter | 2.2 mm |

| Outer Diameter Tolerance | ±3 μm |

| Concentricity Tolerance | ±2 μm |

| Surface Finish Tolerance | ±0.2 μm |

These zirconia tubes are manufactured to the highest standards, ensuring reliable performance in demanding applications.

Small Size Ceramic Rod for Precision Liquid Delivery Systems

Key Features:

Applications:

This zirconia rod is essential in modern healthcare settings, where accuracy and reliability in liquid delivery are crucial for successful outcomes.

| Item Name | Zirconia Ceramic Rod |

| Length | 30 mm |

| Diameter | 1.3 mm |

| Diameter Tolerance | ±5 μm |

| Surface Finish Tolerance | ±0.2 μm |

| Concentricity Tolerance | ±2 μm |

Zirconia Plungers: Essential Components for Fluid Transfer in Pumps and Compressors

Zirconia plungers are primarily used for the efficient transfer of fluids in various applications, including:

In the cylinder, the plunger is pushed and pulled back and forth, with seals installed between the plunger and the cylinder. This reciprocating motion expels fluid from the cylinder and directs it through the outlet to other chambers or modules. Zirconia plungers are widely used in demanding environments such as fracturing pumps, injection pumps, cleaning pumps, metering pumps, and oil extraction pumps. Their surfaces undergo mirror polishing treatment, ensuring optimal performance and durability.

| Item Name | Zirconia Plunger |

| Length | 80 mm |

| Diameter | 12mm |

| Diameter Tolerance | ±2 μm |

| Concentricity Tolerance | ±2 μm |

| Surface Finish Tolerance | ±0.2 μm |

Final Packaging and Delivery of Ceramic Components

Once the ceramic components pass quality inspection, they are carefully packaged based on volume, weight, and delivery timelines. Depending on the agreed shipping terms in the contract, we offer three transportation options: sea freight, air freight, or land transportation. The products are then transferred to the logistics department for secure packaging and timely delivery, ensuring they reach their destination as specified.

After-Sales Services

Quality Issue Resolution: Any issue where the product does not meet the agreed-upon standards upon receipt, WEIERT offers a return or exchange service. Depending on the situation, we will also provide repair or reprocessing options. Any additional after-sales costs due to product quality issues will be covered by WEIERT.

Technical Support: WEIERT provides customers with comprehensive material performance consultations, offering guidance on the use of ceramic components. Additionally, we provide detailed technical parameters to ensure that out clients promote their projects smoothly.

Our Commitment to Sustainability

At WEIERT, we are dedicated to environmental stewardship and sustainable development. In China, we have launched a Ceramic Component Recycling Program.

We invite our local customers to return damaged or obsolete ceramic components to us for environmentally responsible processing. This initiative is part of our mission to create a greener, more sustainable future for our local communities.