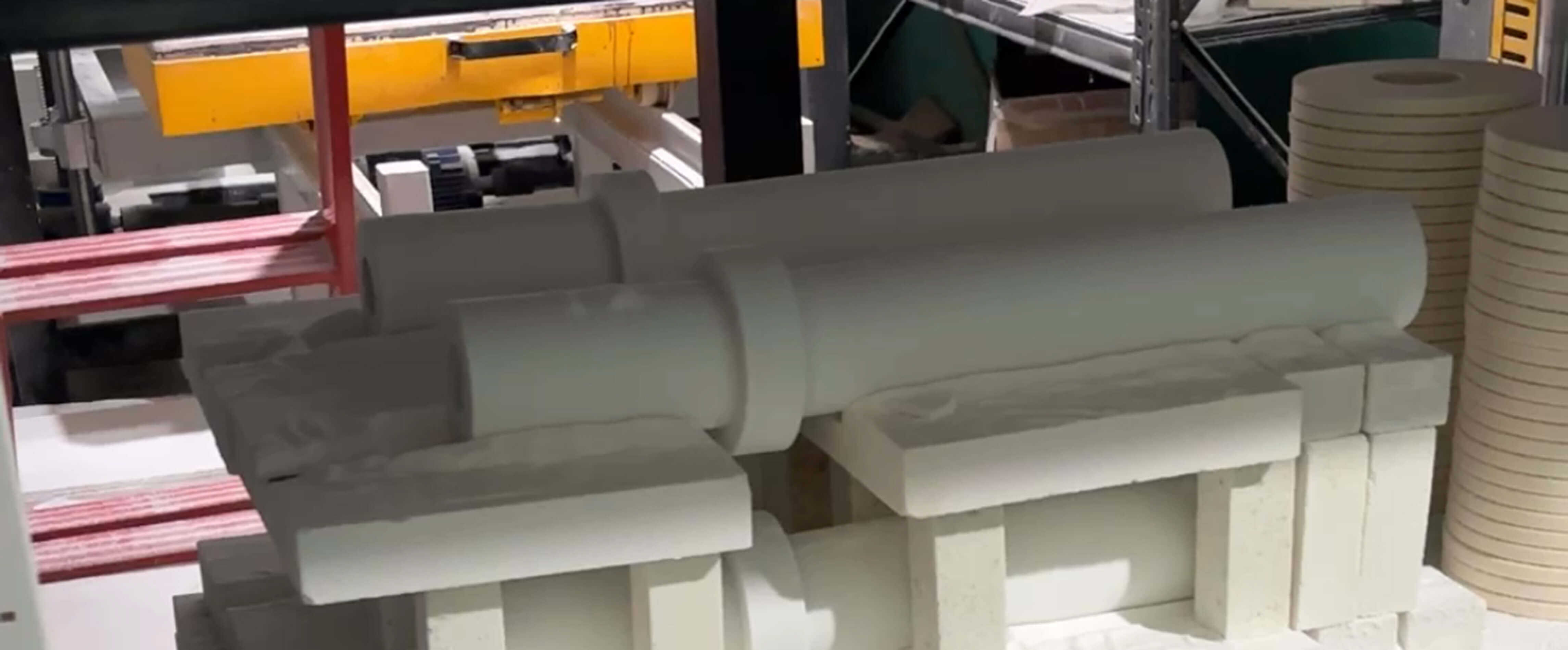

Pulping Equipment Ceramic Parts, Ceramic Cones

Ceramic cones are essential components used in pulping equipment such as grinders, turbo separators, vacuum pumps, and refiners. They play a crucial role in high-density cleaners specifically designed for the paper and paper recycling industry. These cones are responsible for filtering out unwanted particles from the stock, including metals, stones, plastics, and other debris. Typically, these are large ceramic parts, measuring nearly 1 meter in length. They are usually made from a blend of alumina (Al₂O₃) and zirconia (ZrO₂), and are often encased in stainless steel for added protection. The dimensions of these cones can be customized to meet client specifications.

The manufacturing process generally falls into two categories: segmental fabrication and monolithic forming. Segmental manufacturing significantly reduces production difficulty and costs. However, for applications requiring high strength and durability, monolithic forming is preferred. It’s worth noting that as the size increases for monolithic parts, the complexity of machining also rises.

These ceramic cones are highly wear-resistant and corrosion-resistant, resulting in an extended service life and reduced maintenance frequency, which ultimately lowers operational costs and labor expenses.

Large Ceramic Tubes for Vacuum and Electrode Boilers

These ceramic tubes measure 1 meter in length, with a wall thickness of 34 mm and a diameter of 100 mm.

Large Ceramic Rings

These alumina ceramic rings are utilized in specific production processes within the semiconductor manufacturing industry. We can provide rings with a maximum size of 500 mm in diameter and 500 mm in height.