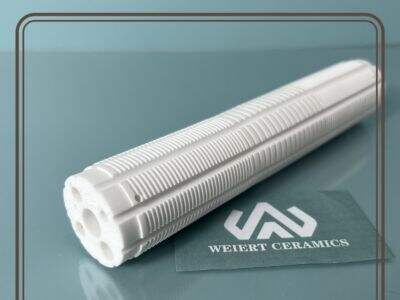

Which makes Alumina ceramics a truly amazing materials which be used in many applications due to the mentioned features. Understanding in detail why alumina ceramic by Weiert Ceramics are so innovative.

Strength and Endurance That Lacks in No Match

Its strength and toughness are unmatched: This is due to the fact that alumina ceramics have extremely high levels of hardness. They can even tolerate really high pressure without breaking or cracking. Now this quality makes them highly usable especially with machines working under heavy pressurized conditions in industrial areas. They also pack a lightweight nature for easy maneuverability alongside installation.

Excellent resistance to very high and low temperatures

The most interesting attribute of alumina ceramics is that they can withstand high temperatures. These ceramics are the heroes of them all as they endure through whatever level heat or cold you put them. This is the main reason why they are well known for applications like furnace linings and kiln components. In addition, alumina ceramics are also known for their extraordinary thermal stability: they will keep the preferred shape no matter how much heat is added or removed. Surely, the superheroes of the ceramic world.

Superior Heat and Electrical Insulation

Alumina ceramics exhibit excellent thermal and electrical insulating properties. Their functionality in blocking heat and electricity which have made their use indispensable particularly for applications needing dissipation of energy transference such as electrical components, high-powered transformers. This is where the alumina ceramics come as ideal materials for critical operations.

Superior Corrosion and Wear Resistance

Also, alumina ceramics have a high resistance to corrosion and abrasion. This makes them safe and resistant to some strong chemicals that can be used on a lot of materials. Their rust proof nature, is actually why they are quite commonly used in applications like chemical processing plants to handle various corrosive materials. Its resistance to wear means it lasts longer which makes alumina ceramic material cost effective in the long run.

Applications Widely Applicable to Nearly All Industries

One impressive quality of alumina Ceramics is its multidisciplinary features in a business segment. Aerospace and medical industries to automotive applications, alumina ceramics have many uses in products that range from cutting tools to ball bearings and dental implants. This adaptability has made them an indispensable part in many professions.

In summary, alumina ceramic is an excellent material that plays an indispensable part in a plethora of industrial applications. The attributes that give them the ability to be as strong if not stronger than steel, survive high and low temperatures, become one of the best insulators with zero thermal conductivity while at or near absolute zero (again heating systems and scientific research), corrosion resistant in all conditions including hydrochloric acid found naturally nearby a super volcano undersea; sea water too unless it becomes live-steam for which only platinum resists better. So, when you see a machine working tirelessly for longer hours and still able to deliver constant performance without degrading quickly can all happen through alumina ceramics.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA