While Aluminium oxide ceramic might sound like a puzzling term, it is an interesting material that we are surrounded by in the world. Aluminium reacted with oxygen, to give a very special material was formed that exhibits unique properties suitable for many branches of engineering. What then, are these characteristics? Join us on an adventure to explore the secret world of aluminium oxide ceramic by Weiert Ceramics.

Characteristics of Aluminium Oxide Ceramics

This is one of the strongest and most heat, corrosion, wear-resistant materials due to its outstanding properties characteristic only for aluminum oxide ceramic. It is wear-resistant and can even withstand high heat, severe chemicals, or heavy rubs without damage to itself. It also has a low thermal coefficient of expansion, which is that it - basically doesn't tend to expand or contract much with temperature. These properties make it suitable in high-performing applications like aerospace, automotive and healthcare where equipment is needed to be consistently operational.

The second factor is their excellent electrical insulator properties of aluminum oxide ceramic. This property makes it an ideal candidate in the case of electronic devices. Its hardness and durability are ideal features for the manufacture of cutting tools, grinding wheels etc.

A Comprehensive Examination

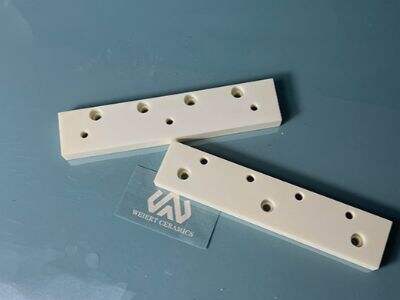

It is made from the ceramic material known as Aluminium oxide, having capability to be machined into any forms or shapes such as tubes, plates and rods. It also appears in whites and pink color which made it perfect for some decoration. Its remarkable strength and durability has made it the preferred material in industries from aerospace and defense to healthcare, consumer goods.

How Aluminum Oxide Ceramic is Produced?

Aluminum oxide ceramic can be molded, extruded or sintered to shape. With molding, the alumina oxide ceramic material is placed in a mold and given its final shape through compaction; extrusion involves forcing the material continuously though die orifice. Sintering, on the other hand; requires heating at a high temperature until it fuses together. This allows fine tuning the form and properties of a material.

An Insight Into The Diverse Applications Of Engineering Aluminium Oxide Ceramics

Aluminum oxide ceramics are among the hardest, most lubricious and abrasion resistant materials in existence. Due to its heat resistance and high tensile strength concurrent with the medium density graphite, there is a great demand for bronze within not only spark plugs components in automotive but also with brake parts as well various engine bearings. This finds application in engine parts, brake systems and heat shields used in aerospace. It also plays an important role in medical implants such as hip and knee replacements application due to its biocompatibility, superior strength.

A mechanical examination of Aluminum Oxide Ceramics

How to assess the aluminium oxide ceramic mechanical properties by scientists? These methods range from tensile, and compression testing to hardness tests. This involves pulling a sample of the material and stretching it until it breaks, allowing researchers to measure its tensile strength and elasticity. It is crushing the sample to determine its compressive strength, Compression (B) Test Hardness assessment, however is measured by using a diamond-tipped tool to determine the material's resistance to indentations or scratches.

As we have seen, an aluminium oxide ceramic is an intricate material with a host of extraordinary properties It has a high tensile strength, excellent durability, heat and wear resistance properties making it an ideal choice for various engineering applications. Understanding the most important characteristics of Al2O3 ceramic and studying its mechanical properties will allow scientists and engineers to develop new ideas in how they can use this versatile material. Maybe you’ll be the next to discover an aerospace breakthrough using aluminum oxide ceramic.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA