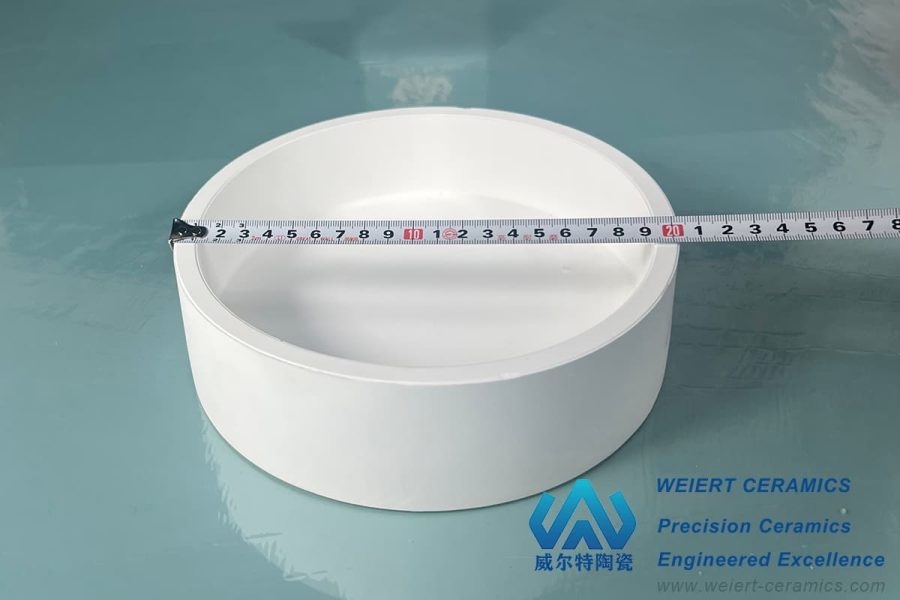

بوتقة المغنيسيا MgO

بوتقة أكسيد المغنيسيوم

في مجال علم المعادن عالي الحرارة وعمليات الصهر بالحث، تؤثر نقاوة البوتقة واستقرارها بشكل مباشر على نظافة وأداء المادة النهائية. وبالنسبة للشركات التي تنتج السبائك الفائقة القائمة على النيكل، والمعادن الثمينة، والسيراميك المتقدم، أصبحت بوتقة أكسيد المغنيسيوم عالية النقاء (MgO) حاوية حرارية أساسية بشكل متزايد.

يتميز أكسيد المغنيسيوم (MgO) بالخصائص التالية:

- درجة انصهار مرتفعة تصل إلى 2,852 °C؛

- مقاومة عالية لأكاسيد المعادن والخبث القلوي

- استقرار كيميائي أعلى مقارنة بأكسيد الألومنيوم (Al₂O₃)؛

- عزل كهربائي جيد ومعامل تمدد حراري منخفض نسبيًا.

تجعل هذه الخصائص MgO مادة البوتقة المفضلة لأفران الحث، وأفران الصهر بالحث، ومعدات الصهر بالحزمة الإلكترونية.

نهج التصنيع لدى WEIERT Ceramics

استنادًا إلى الدراسات المتعلقة بسيراميك MgO عالي النقاء (مثل البيانات الصناعية التي تُظهر محتوى MgO يتجاوز 99٪ وكثافة حجمية مرتفعة)، تعتمد Weiert Ceramics تقنيات تشكيل وتنقية متقدمة لضمان استقرار بنيوي ممتاز وتجانس عالٍ.

- تجمع عمليتنا بين الكبس متساوي الضغط على البارد (CIP) لتحقيق توزيع جسيمي متجانس وكثافة عالية، وبين إعادة التبلور بالانصهار الكهربائي للحصول على حبيبات موجهة ومستويات شوائب منخفضة للغاية.

- ومن خلال التحكم الدقيق في ظروف التلبيد واستخدام مواد MgO فائقة النقاء، تصل البوتقات الناتجة إلى نقاوة تتجاوز 99.5٪ وكثافة حجمية تقارب 3.4 g/cm³، مما يوفر ثباتًا حراريًا وكيميائيًا متميزًا.

مقاومة التميؤ والاستقرار طويل الأمد

نظرًا لقابلية MgO للتميؤ، نعتمد التحسينات التالية:

- إضافات دقيقة من Al₂O₃ وCaO وGa₂O₃ لتحسين التلبيد وتقليل المسامية المتبقية؛

- طلاءات سطحية بتقنية السول–جيل لسد المسام؛

- تغليف محكم بالتفريغ مع التحكم في الرطوبة أثناء التخزين والنقل.

الأداء والتطبيقات

تُستخدم بوتقات MgO عالية النقاء في:

- الصهر بالحث للسبائك الفائقة القائمة على النيكل؛

- تنقية البلاتين والإيريديوم والبلاديوم وغيرها من المعادن الثمينة؛

- صهر مواد السلائف لكاثودات بطاريات الليثيوم-أيون، وأكاسيد العناصر الأرضية النادرة، ومصهورات المعادن عالية النقاء.

تشير بيانات المصنع المستقلة إلى أن بوتقات Weiert Ceramics تحقق تشغيلًا مستمرًا لأكثر من 20 ساعة دون فشل بنيوي في بيئة فراغية عند 1,700 °C.

الخلاصة

تمثل بوتقات MgO عالية النقاء الاتجاه المتقدم لمواد السيراميك الحرارية. ومن خلال استخدام مواد خام فائقة النقاء وعمليات تلبيد مخصصة، تقدم Weiert Ceramics حلول بوتقات ذات نقاء أعلى وعمر خدمة أطول.

المراجع:

- Jin Yan, Development of Magnesia Crucible Products, Ceramics, 2006.

- Chen Guangyao et al., Interface Reaction Mechanism between MgO Crucible and Ni-Based Superalloy, Journal of the Chinese Ceramic Society, 2024.

- Wu Chaowan, Studies on MgO Crucible in Vacuum Induction Furnace for Pure Iron Melting, Acta Metallurgica Sinica, 1964.