Daar is verskeie soorte smeltkroeë beskikbaar, elkeen ontwerp om aan spesifieke toepassingsbehoeftes te voldoen. Dit sluit in alumina, magnesia, sirkonium, boornitried, silikonkarbied, grafiet en kwarts smeltkroeë. Elke materiaal bied unieke termiese weerstand en chemiese stabiliteit, wat hulle geskik maak vir verskillende hoë-temperatuur eksperimente en industriële prosesse.

Prestasievoordele van smeltkroesmateriale

Alumina-smeltkroes

Sirkoon-smeltkroes

Magnesia Crucible

voordele: Magnesia-kroesies het uitsonderlike weerstand teen alkaliese metaalslakke en is hoogs doeltreffend in vakuumsmeltprosesse, veral wanneer dit met hoë-temperatuur raffineringsbehandelings gebruik word. Wanneer dit gekombineer word met deoksideerders soos koolstof (C) en aluminium (Al), fasiliteer hierdie smeltkroeë die produksie van CO-gas en Al₂O₃-insluitings, wat vrye suurstof doeltreffend uit gesmelte staal verwyder sonder om drywende slak tydens die smeltproses te genereer. Omdat magnesia egter geneig is om te vervlugtig by temperature bo 2300°C, moet magnesia keramiekprodukte by temperature onder 2200°C gebruik word.

Disadvantages : Die primêre nadeel van magnesia-kroesies is hul neiging om te ontbind, wat vrye suurstof en magnesium vrystel soos die vakuumvlak en raffineringstemperatuur toeneem. Wanneer die werklike suurstofinhoud in die gesmelte poel onder die versadigingsvlak van opgeloste suurstof van die vuurvaste voering daal, begin die voering suurstof aan die gesmelte staal verskaf. Daarom, wanneer hoë-temperatuur legeringsgrade met behulp van magnesia smeltkroeë gesmelt word, is dit van kardinale belang om raffineringstemperatuur en -tyd noukeurig te beheer om die ontbinding van die smeltkroes en die ongewenste suurstoftoevoer na die gesmelte staal te voorkom.

Grafiet smeltkroes

voordele: Grafiet-kroesies is hoogs bestand teen hoë temperature en beskik oor uitstekende termiese geleidingsvermoë. Hulle toon ook sterk weerstand teen korrosie deur suur en alkaliese oplossings, wat hulle 'n koste-effektiewe opsie maak. Grafiet-kroesies word wyd gebruik vir die smelt van verskeie nie-ysterhoudende metale soos goud, silwer, koper, aluminium, lood en sink, sowel as vir mediumkoolstofstaal en skaars metale. Hulle is versoenbaar met verskillende soorte oonde, insluitend kookoonde, olie-oonde, gasoonde, elektriese oonde en medium- tot hoëfrekwensie-induksie-oonde.

Disadvantages : Die primêre beperking van grafiet-kroesies is hul swak termiese skokweerstand. Na verhitting moet hulle nie aan skielike afkoeling onderwerp word nie, aangesien dit skade aan die smeltkroes kan veroorsaak.

Quartz Crucible

voordele: Kwartskroes spog met hoë deursigtigheid, uitstekende hittebestandheid en 'n lae termiese uitsettingskoëffisiënt. Gemaak van hoë-suiwer kwartssand, hierdie smeltkroeë is bekend vir hul hoë suiwerheid, duursaamheid en vermoë om uiterste temperature te weerstaan.

aansoeke: Hulle word wyd gebruik in die halfgeleier- en fotovoltaïese industrieë, veral in die produksieprosesse van monokristallyne silikonstawe. Kwartskroes speel 'n kritieke rol in die smelt van silikonmateriaal en die groei van kristalle, wat dit onontbeerlike verbruiksartikels maak in die vervaardiging van halfgeleierwafels en fotovoltaïese silikonwafels. In kristalgroeioonde dien kwartskroesies as verhittingshouers, wat polikristallyne silikonmateriaal direk hou, wat gesmelt word en dan in silikonstawe/wafers verwerk word vir verdere gebruik in stroomafwaartse halfgeleierskyfies, fotovoltaïese selle en ander produkte.

Disadvantages

: Die belangrikste beperking van kwarts smeltkroeë is hul beperkte lewensduur, wat tipies wissel van 360 tot 500 uur se gebruik. Absorbeer water maklik en is geneig tot vog; voorverhitting en bak is nodig voor gebruik.

Silikonkarbied SiC-smeltkroes

Disadvantages : Ten spyte van hul vele voordele, het silikonkarbied-kroesies beperkings. Hulle vertoon verminderde weerstand teen alkalimetaaloksiede en is vatbaar vir vogabsorpsie. Vinnige verkoeling of verhitting moet vermy word, aangesien dit tot krake kan lei. Daarbenewens kan die gebruik van vloeistowwe die smeltkroes se lewensduur verkort.

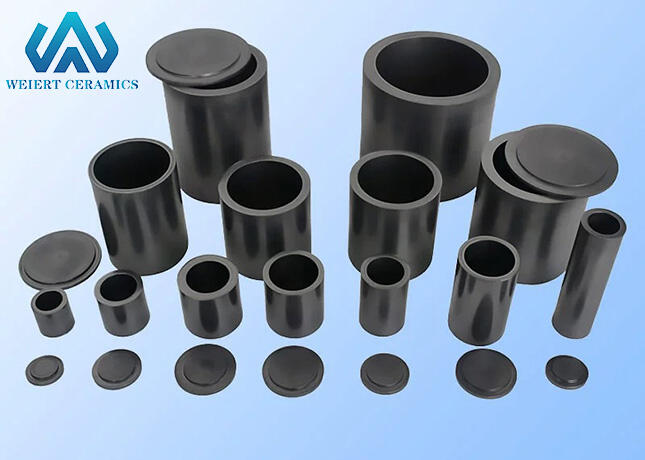

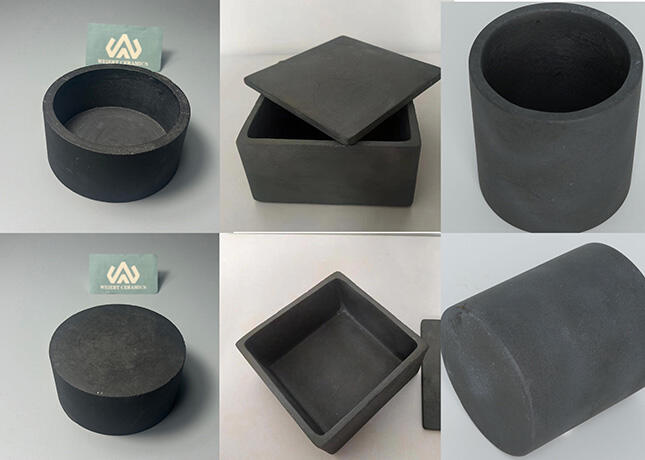

Keramiek-kroesies: 'n Kernproduk van WEIERT

Op soek na persoonlike keramiek smeltkroes verskaffer? WEIERT spesialiseer in die verskaffing van hoë gehalte keramiek smeltkroeë wat pasgemaak is vir jou behoeftes. Verskaf eenvoudig jou vereiste afmetings en materiaalspesifikasies. Onseker oor die beste materiaal? Deel jou toepassingsvereistes, en ons kundiges sal die ideale oplossing aanbeveel. Geen minimum bestelhoeveelheid benodig nie.